Recently updated on May 27th, 2024 at

HAKUSAN, ISHIKAWA—Nakamura-Tome Precision Industry Co., Ltd. (CEO Shogo NAKAMURA) has announced a newly developed chip-breaking function, “Triangle Cut.” The Triangle Cut can be applied to all slide-guided machines, including box-way machines that cannot utilize the Oscillating Cutting function*1. With this announcement, it is now possible to install a chip-breaking function in all of Nakamura’s model lineup.

*1 Please refer to the following link regarding the Oscillation Cutting.

https://www.nakamura-tome.com/oscillation_cutting/

■What is the Triangle Cut?

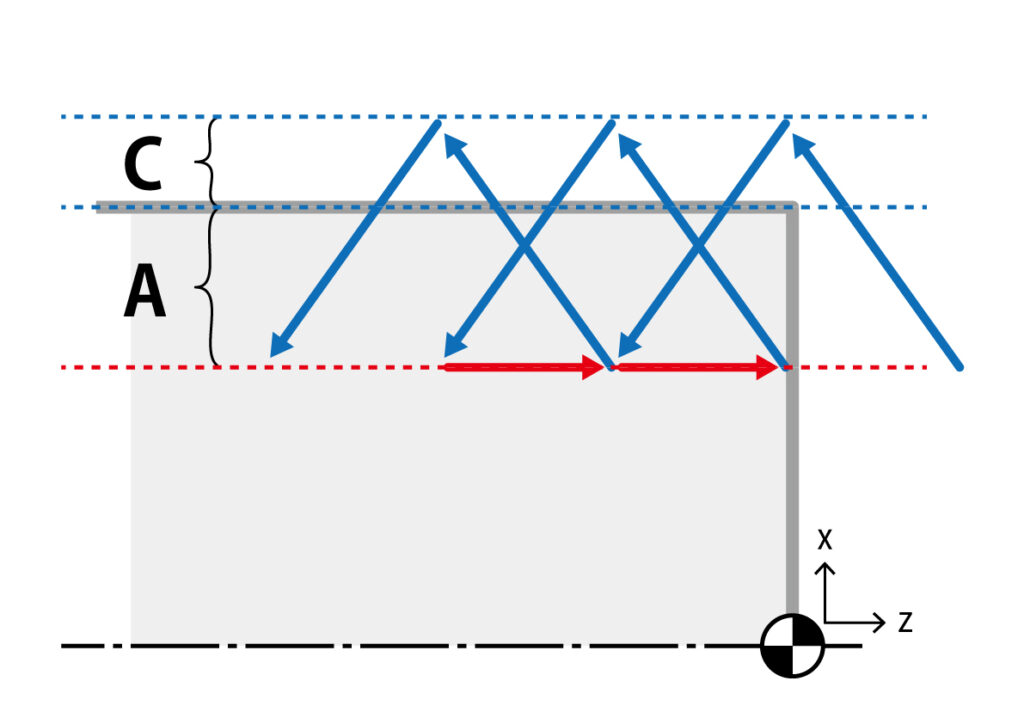

It is an optional function that processes while breaking chips by operating the turning path in a triangular shape. Drawing a triangular path moves the cutting edge away from the workpiece, and the chips are divided due to air cutting.

■YouTube

https://youtu.be/e86LmnMBP5s

■How to use the Triangle Cut?

The Triangle Cut can be applied to a concerned machining program section by enclosing it with dedicated G codes of G338 (start code) and G339 (end code).

G338 A__. B__. [C__.] D__. …Turn on the Triangle Cut

G01 Z-10. F0.2

X60.

X70. Z-15.

G339 …Turn off the Triangle Cut

A:Finish allowance (A+C = the height of the triangle)

B:Spindle rotation speed until completion of triangle hypotenuse (two hypotenuses) operation

C:Clearance amount

D:Machining direction

■Advantages and Disadvantages

Compared to the Oscillation Cutting, the Triangle Cut tends to reduce the deterioration of surface roughness and can be suppressed to 1.2 to 2 times the level of normal turning. On the other hand, the machining time could be 2.7 to 3 times longer due to the extension of the processing path.

| *2 | Triangle Cut | Oscillation Cutting |

|---|---|---|

| Chip-breaking performance | ◎ | ◎ |

| Surface roughness (Ra) | 1.2 to 2 times | 3 to 4 times |

| Machining time delay | 2.7 to 3 times | Almost equivalent |

| Applicable models | All models | 21 models *3 |

*2 Comparison in the finishing process

*3 Only the X/Z axis of the linear-guided machines can be applied.

■Development background

The cutting chip problem is unavoidable for production sites, and the burden on the production site caused by this problem is also heavy. With the evolution of machinery and servo technology, the Oscillating Cutting function has been put into practical use, and its programming can easily solve chip problems. However, the Oscillation Cutting is difficult to apply to box-way machines because they are at risk of damage due to the high-speed movement of the Oscillation Cutting.

We have received numerous inquiries regarding the application of Oscillation Cutting to box-way machines. To address this issue, we searched for a way to divide the chips reliably and developed the Triangle Cut.

Instead of using a special program, we have devised a way to perform chip-breaking operations by adding simple G-code modifications to the processing program already in use.

We hope you will use it as a function to solve the chip problem in the field.

■Ask Nakamura-Tome

https://www.nakamura-tome.com/contact_product/

【Corporate Information】

Business details: Multitasking machine, combined precision CNC lathe

Company: Nakamura-Tome Precision Industry Co., Ltd.

Address: Ro 15, Netsuno, Hakusan city, Ishikawa, 920-2195 Japan

CEO: Shogo NAKAMURA

Established: December, 1960

Website: https://www.nakamura-tome.com

Business details: Multitasking machine, combined precision CNC lathe

【Reference】

Sales Marketing Section, Sales Promotion Department

Nakamura-Tome Precision Industry Co., Ltd.

Phone:076-273-3823

E-mail:nt-mktg@nakamura-tome.co.jp