HAKUSAN, ISHIKAWA – Nakamura-Tome Precision Industry Co., Ltd. (Shogo NAKAMURA, CEO/President) has announced the launch of “Protona”, the conversational NC programming software designed for multitasking machines. With its “Easy, Reliable, and Fast” approach, Protona empowers users to become a “Professional” in NC programming.

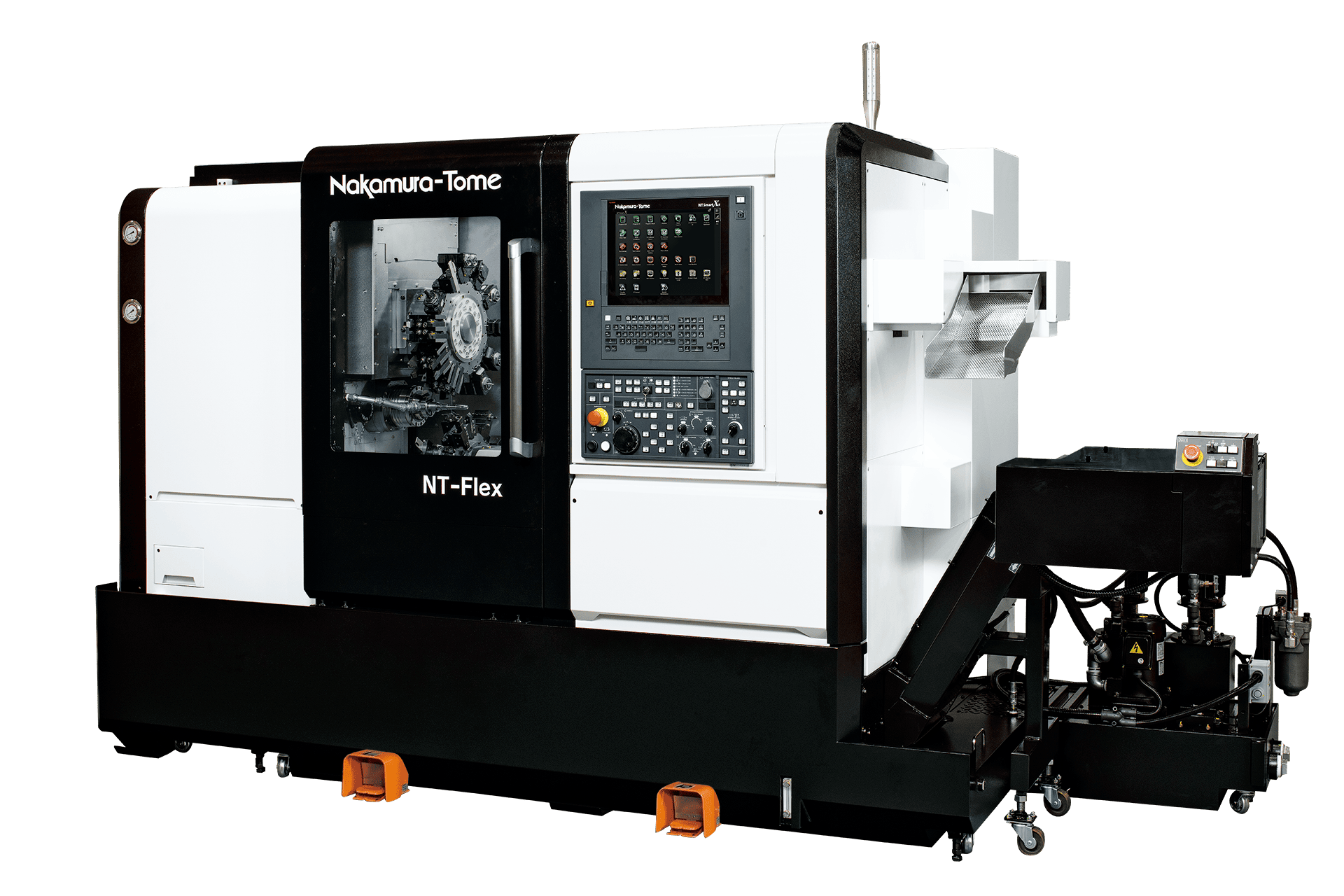

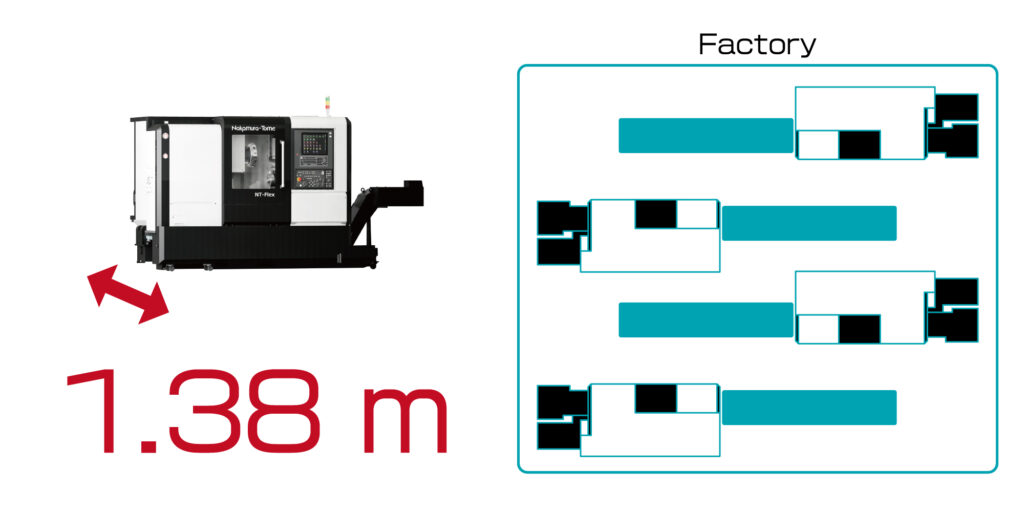

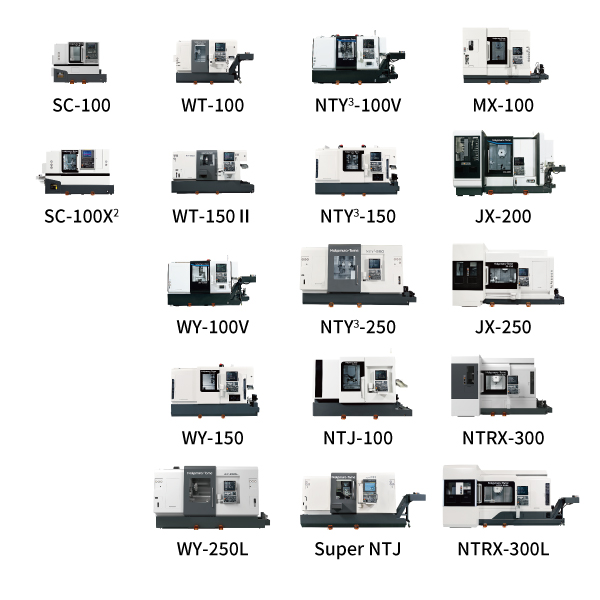

This feature will be included as a standard function on the new NT-Flex model starting at the end of June 2025, and will subsequently be introduced to other models in phases.

An introduction video has been released alongside the announcement. We kindly invite you to view the video below.

YouTube

Title:[New] Protona | Anyone can make NC Programs for Multitasking Machines!

URL:https://youtu.be/EOICl4sx-NU

■Introduction of Protona

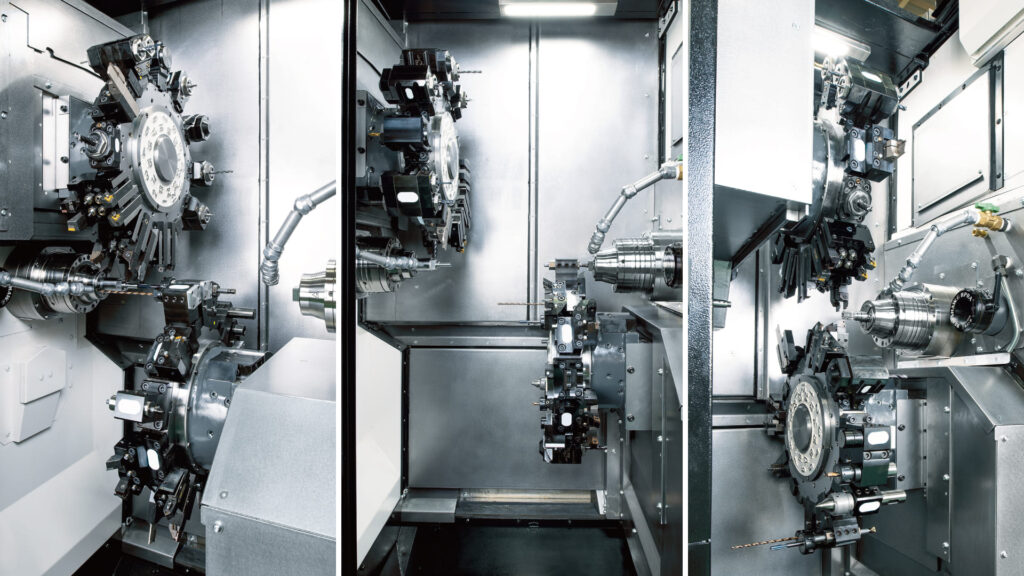

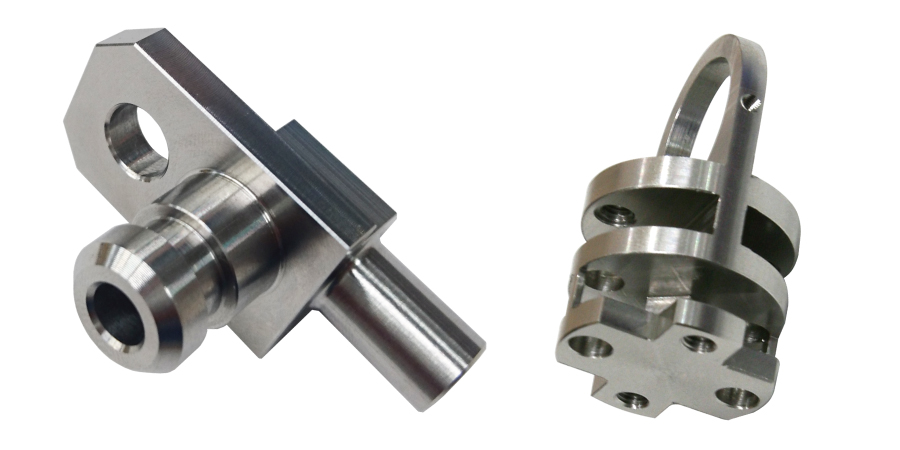

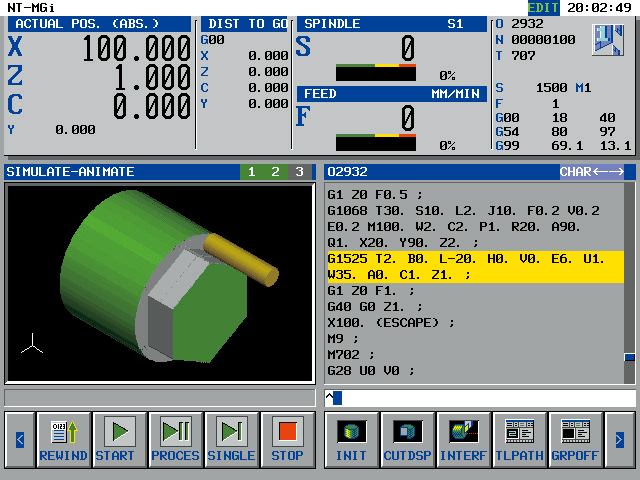

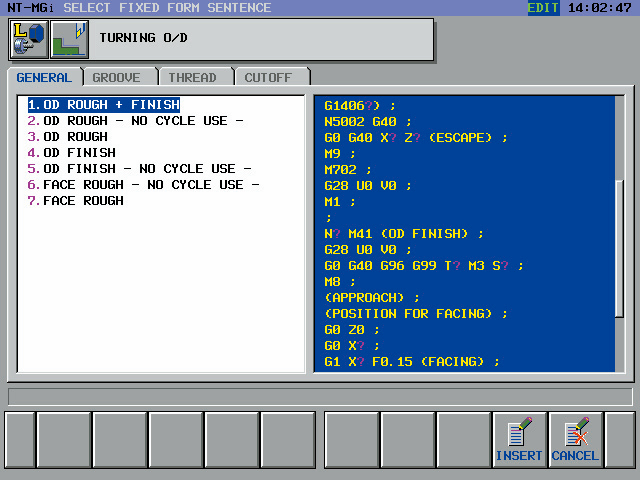

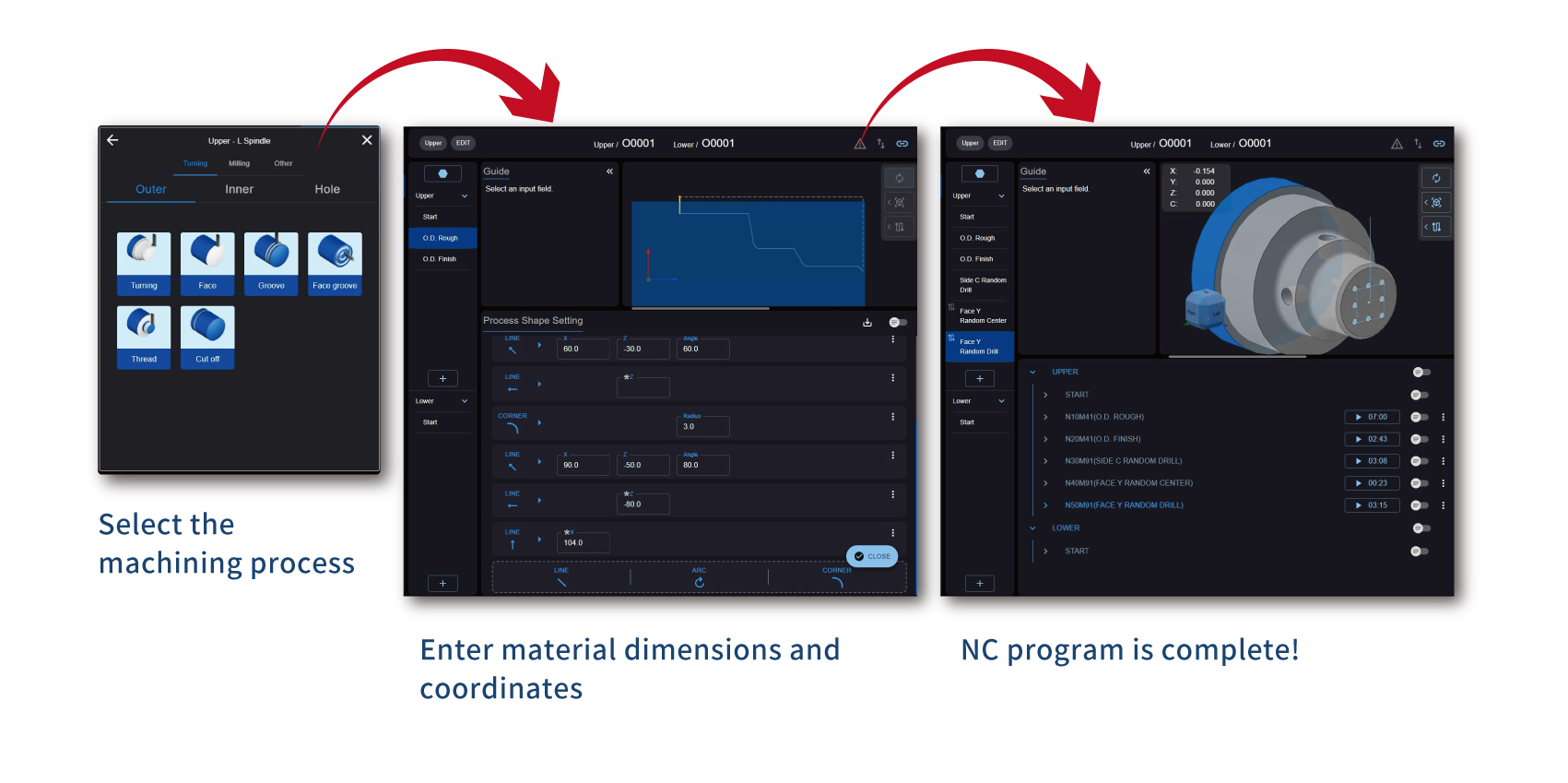

This conversational NC programming software for multitasking machines offers a simpler and more intuitive operation compared to conventional solutions.

Protona enables even less-experienced users—those with basic drawing knowledge—to easily create NC programs without having to memorize enormous programming codes.

*The origin of the name “Protona”

“Pro” stands for Professional and Programming, while “Tona” is derived from the word Tone. Protona is the world’s first conversational NC programming software designed specifically for multitasking machines. It helps users create professional-level programs—much like a finely tuned symphony—bringing precision and harmony to multitasking operations.

■Three Keywords

1. Easy

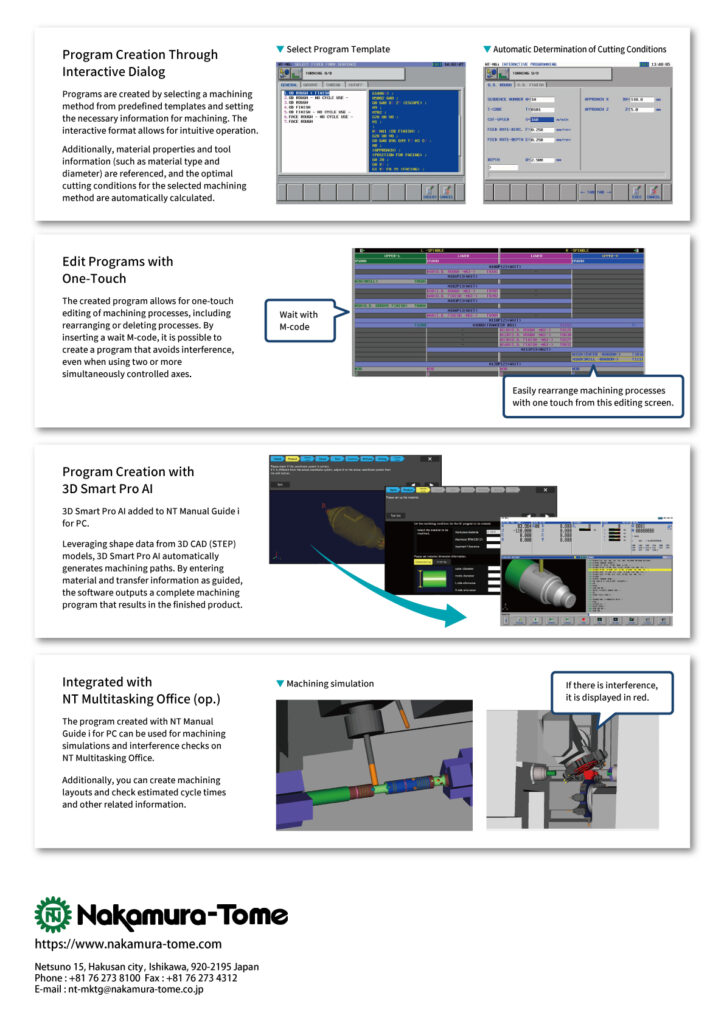

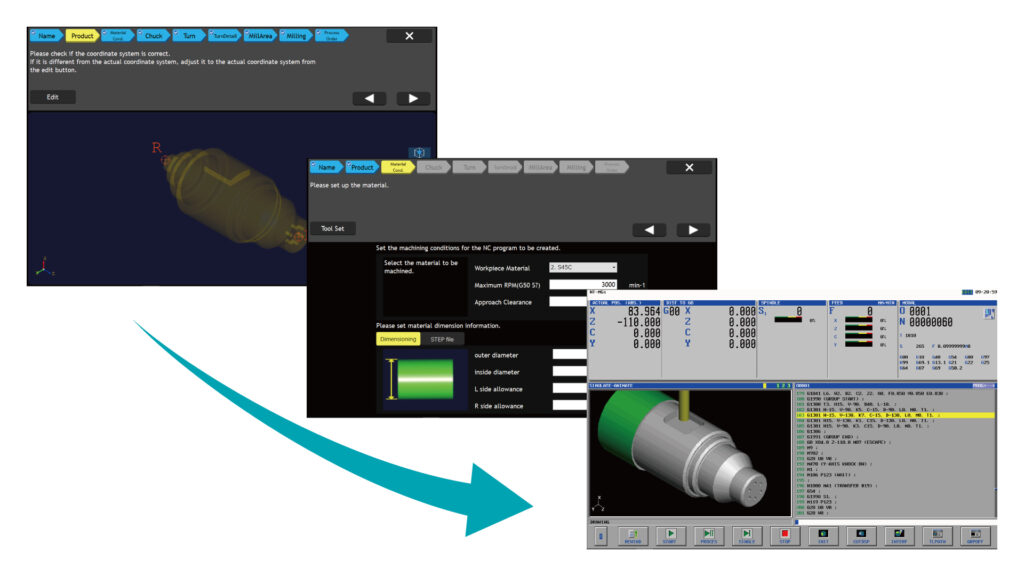

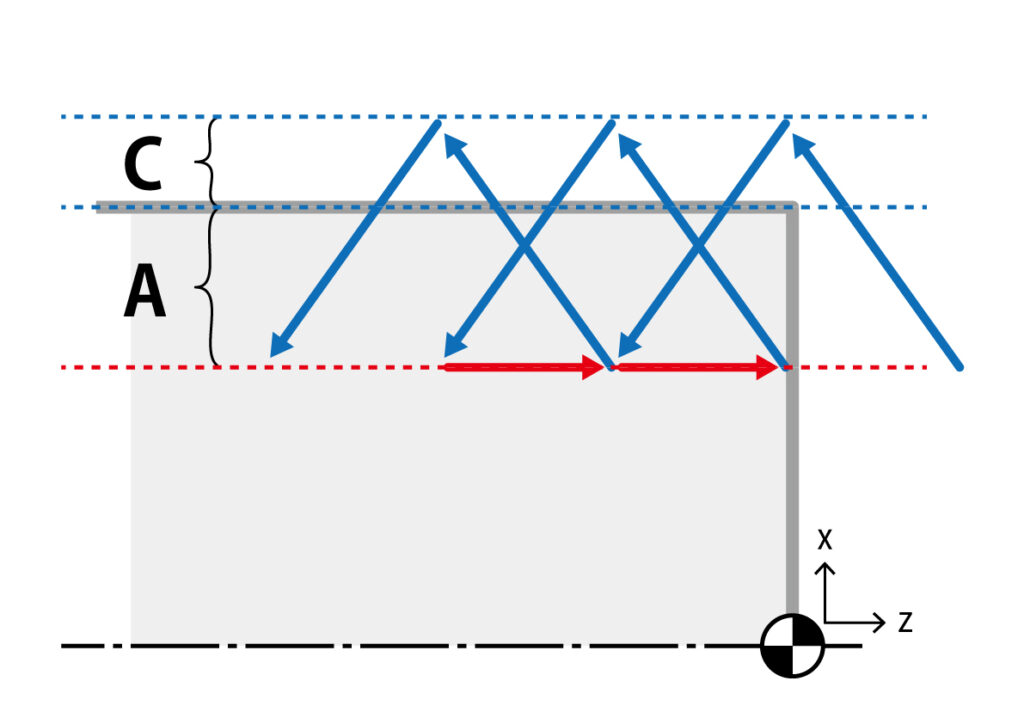

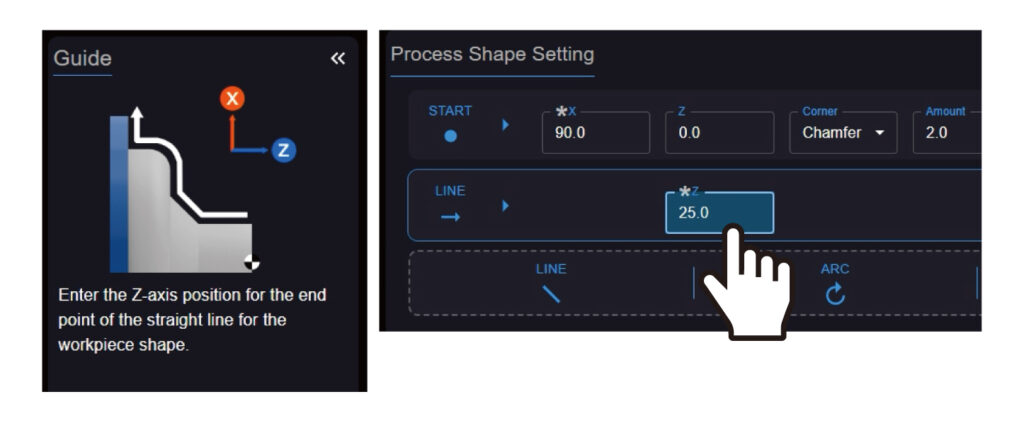

Users can create an NC program through a conversational interface while following on-screen guidance. With clear explanations using both graphics and text, even those without specialized knowledge can use it.

2. Reliable

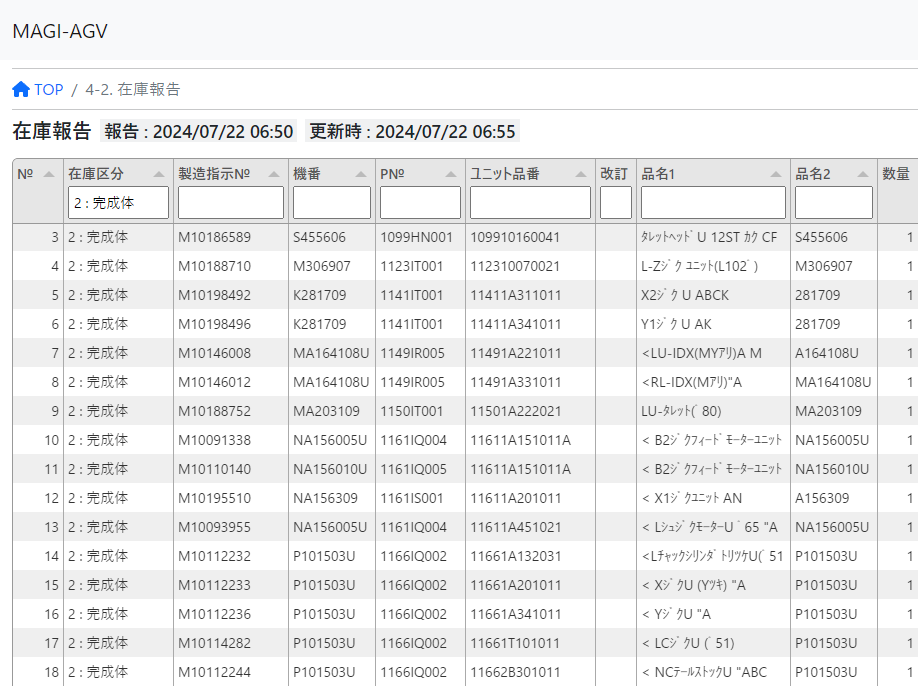

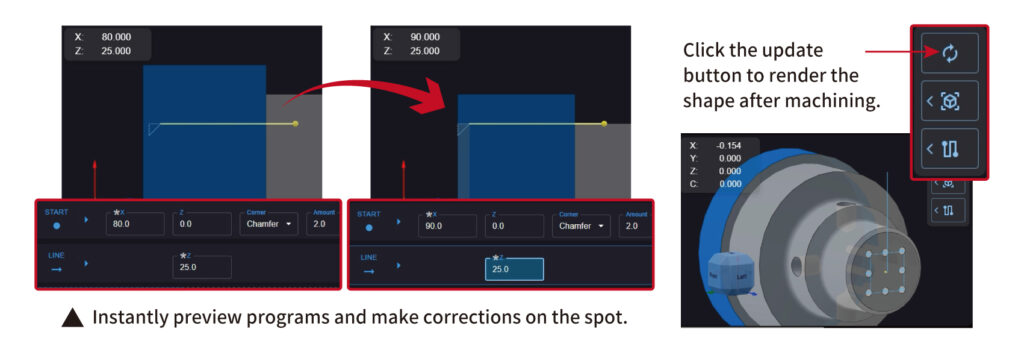

Users can view the machined shapes and machining path on the same screen immediately after creating the NC program.

3. Fast

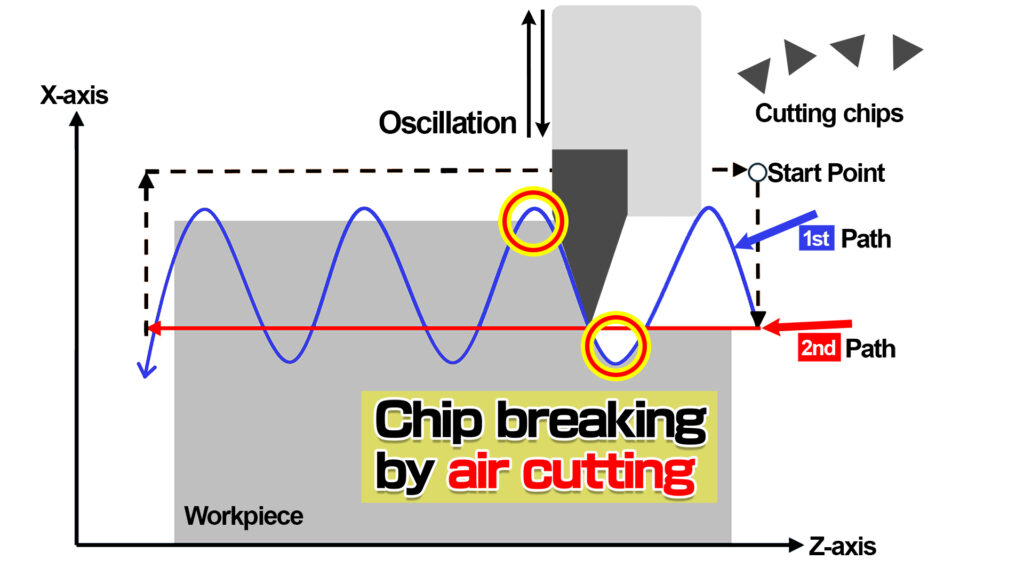

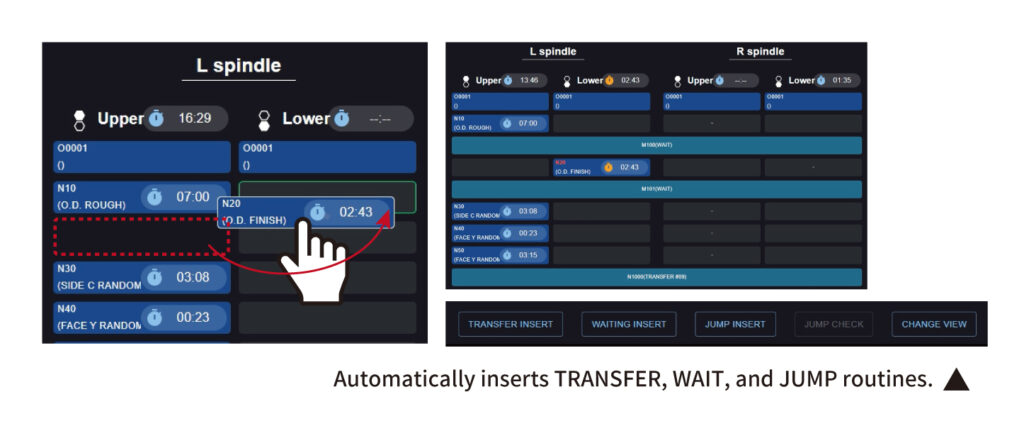

The machining time for each turret head is displayed, and machining processes can be rearranged via drag-and-drop. By adjusting the time balance, users can create NC programs optimized for faster machining. In addition, programming, simulation, and process editing can all be done seamlessly within a single software, enabling users to achieve their desired results more quickly than ever before.

■Further information on Protona

URL:https://www.nakamura-tome.com/software/protona/

■Comment from Shogo Nakamura/CEO

I am very proud to announce “Protona,” the world’s first conversational NC programming software dedicated to multitasking machines. Protona is an innovative tool that empowers users to create professional-level programs for multitasking machines. Conventionally, users have to memorize 50 types of G codes and 100 of M codes when they create NC programs manually. When it comes to programming for multitasking machines, it becomes even more complex, requiring users to learn unique codes for each system and set waiting codes for simultaneous machining. As a result, many customers worldwide consider the time required to become proficient in programming to be a critical issue, especially amid the shortage of operators skilled in handling machine tools.

Protona is the solution to a major challenge faced in today’s manufacturing environments. It allows users to design multitasking machining processes quickly and confidently, without the need to memorize complex codes.

We invite you to experience it firsthand on your shop floor and join us in cutting the burden on your operations!

Ask Nakamura-Tome

https://www.nakamura-tome.com/contact_product/

【Corporate Information】

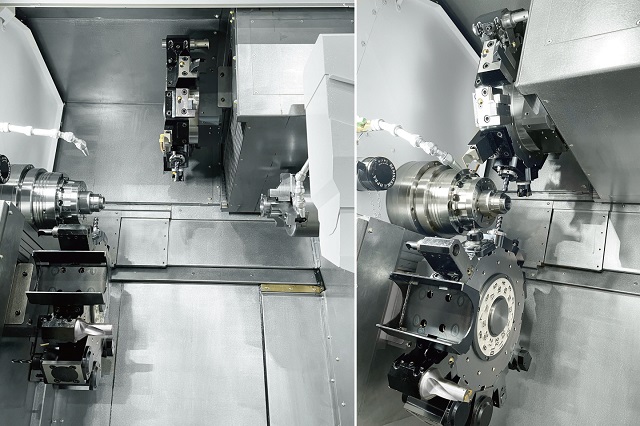

Business details: Multitasking machine, combined precision CNC lathe

Company: Nakamura-Tome Precision Industry Co., Ltd.

Address: Ro 15, Netsuno, Hakusan city, Ishikawa, 920-2195 Japan

CEO: Shogo NAKAMURA

Established: December, 1960

Website: https://www.nakamura-tome.com

Business details: Multitasking machine, combined precision CNC lathe

【Reference】

Nakamura-Tome Precision Industry Co., Ltd.

Phone:076-273-1111

E-mail:nt-mktg@nakamura-tome.co.jp