Recently updated on July 17th, 2024 at

When you think of a machine tool, what comes first in your mind? If you come up with a multitasking machine, please skip this article because you already know the differences of machine tools. If you are new to this topic, why don’t you spend a few minutes with us and think about the machine tools?

1.When do you use a milling machine?

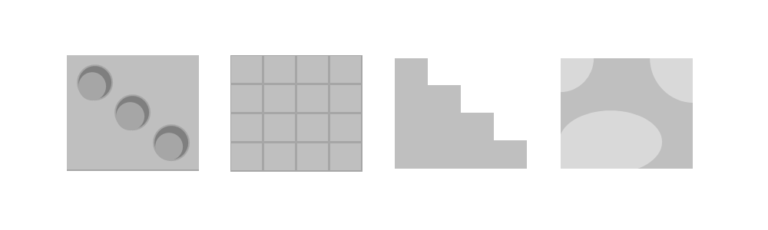

In the purpose of machining a flat surface, you may choose a milling machine. There are basically three types and a manual milling machine is a material cutting device that is not controlled by automation or a computer. A benefit is you can work on machining anytime you want without making or entering a programing, but its machining precision is easily affected by worker’s skill and human error. As the name suggested, an operator should handle it manually that means constant care and attention are required.

To improve work efficiency and stabilize precision, numerical controlled machines were developed and even computer system were embedded on it. They are so called a NC or CNC milling machine. Comparing to the manual machine, they are capable to work on more complicated workpieces and perform more effectively to stabilize the precision. Not only for that, operators do not need to keep staying next to the machine every time. It is more expensive than the manual machine and costs more time to learn about programing, but the NC/CNC machine is the first step in developing an automation strategy.

If you take into account of further efficiency improvement, one of the good solutions is to introduce a machining center, which is a NC/CNC milling machine equipped with an automatic tool changer (ATC). Thanks to the ATC, operators do not need to change tools all over the time any more. 4-axis or 5-axis machines have been developed and much more complicated machining are now available. Since those machines allow tools to simultaneously control not only in the typical X, Y and Z axes but also in the rotating A axis, swerving B axis and/or rotating C axis, workability has been drastically expanded. Furthermore, recent machining centers has a box-type cover to enclose its structure, operators work safely. Needless to say, it costs more than NC/CNC milling machines and needs more time to obtain how to control the machine.

2.How about other machine tools?

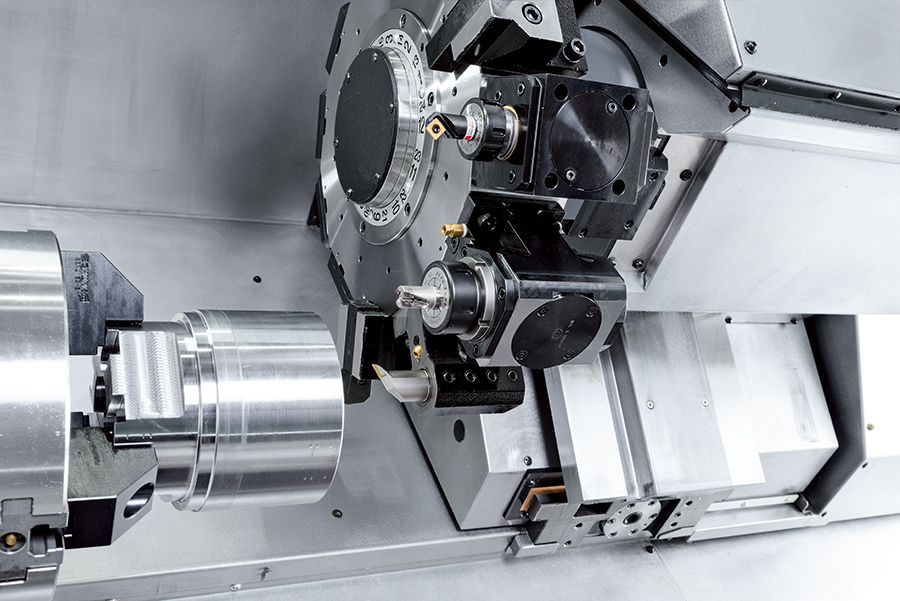

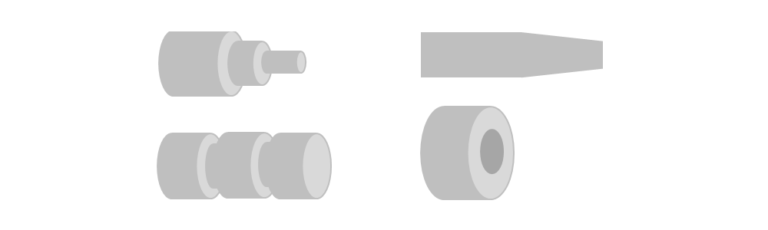

A turning machine (or a lathe) is utilized when you work on cutting a bar material. It grabs the material with chuck jaws and rotates the material to cut the surface roundly like an apple being pealed out by a cutting knife. Turning machines are capable to scrape a cylindrical object to make it closer to a perfect circle, cut it in a tapered shape, make an inner diameter, carve a groove, etc. The machining center rotates its spindle while the turning machine rotates its material. Same as the machining center, the turning machine also varies from the manual type to NC/CNC lathes.

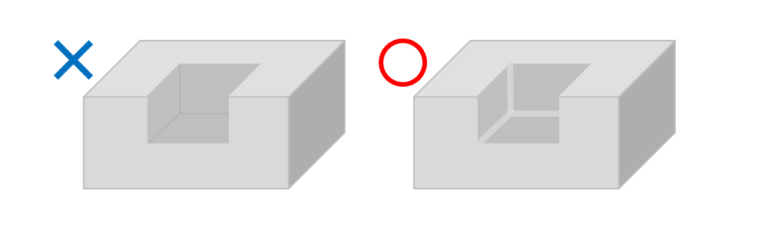

However, it is still difficult to trim a corner R to cut a concave shape with a right angle because basic mechanism of cutting on both machines is rotating. Therefore, if you need to trim the corner R, you should go to a laser machine or wire cutter machine.

3.What if you have a multitasking machine…?

A multitasking machine is a machine combined a turning machine with a machining center, and utilized for multiple cutting processes including turning, milling, drilling, tapering, deep-hole drilling, skiving. If you have one, you will obtain those working abilities at the same time. A material is just a bar when it starts machining, but when it finishes, you will have a completed workpiece without tool change or even without an operator. This is the reason multitasking machines are called “One-hit Machine” in the manufacturing industry.

For the multitasking machine, people think of high volume but actually many manufactures are using this machine for high-mix low-volume, redesigning the conventional manufacturing lines and reducing the time to change the tools.

4.Summary

With the advent of “NC unit” and “ATC device”, the machining centers were developed rapidly and appearing 5-axis machining centers have expanded the variety of machining works more and more.

There are machining centers equipped with the function of lathe turning as well as NC turning machines with the ability of milling like a machining center. Technology is also developed in NC lathes and multitasking machines, so when you select a machine, you should take the measure of compatibility with materials that would be machined in your plant, and determine an appropriate type and specifications.

Nakamura-Tome Precision Industry Co., Ltd is the machine builder of general NC lathes, multi-turret machines, and multitasking machines which have the combined functions of the NC lathes and the machining centers. Please feel free to contact us if you are considering to introduce a machine tool or are stumped about how to select one.