1. We received a request from a customer.

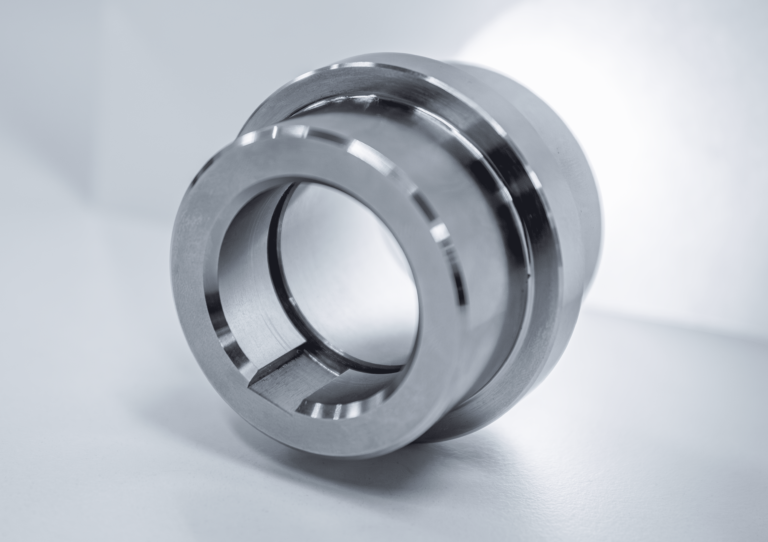

Several methods exist for performing internal keyway milling, including using a slotting machine, a broaching machine, or an electrical discharge machine. On the other hand, we have heard many customers requests, “It would be easier if I could use a multitasking machine to do the machining together with turning, milling and drilling.” When we heard their voices, we really wanted to make it happen, so we looked around for various tool manufacturers.

That’s when we came across this tool!

2. Features of the slotting tool

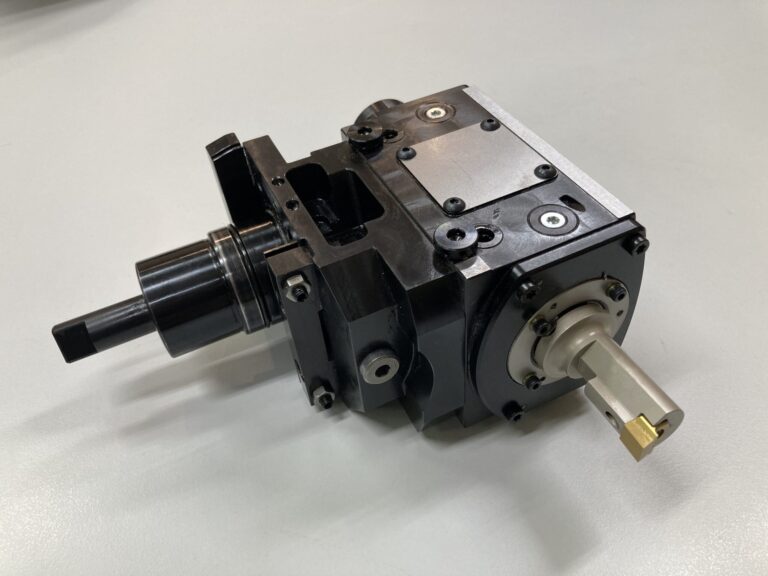

It’s called a slotting tool. This is a slotting tool made by BENZ in Germany. Brighetti’s tools are also famous.

The idea behind them is very unique.

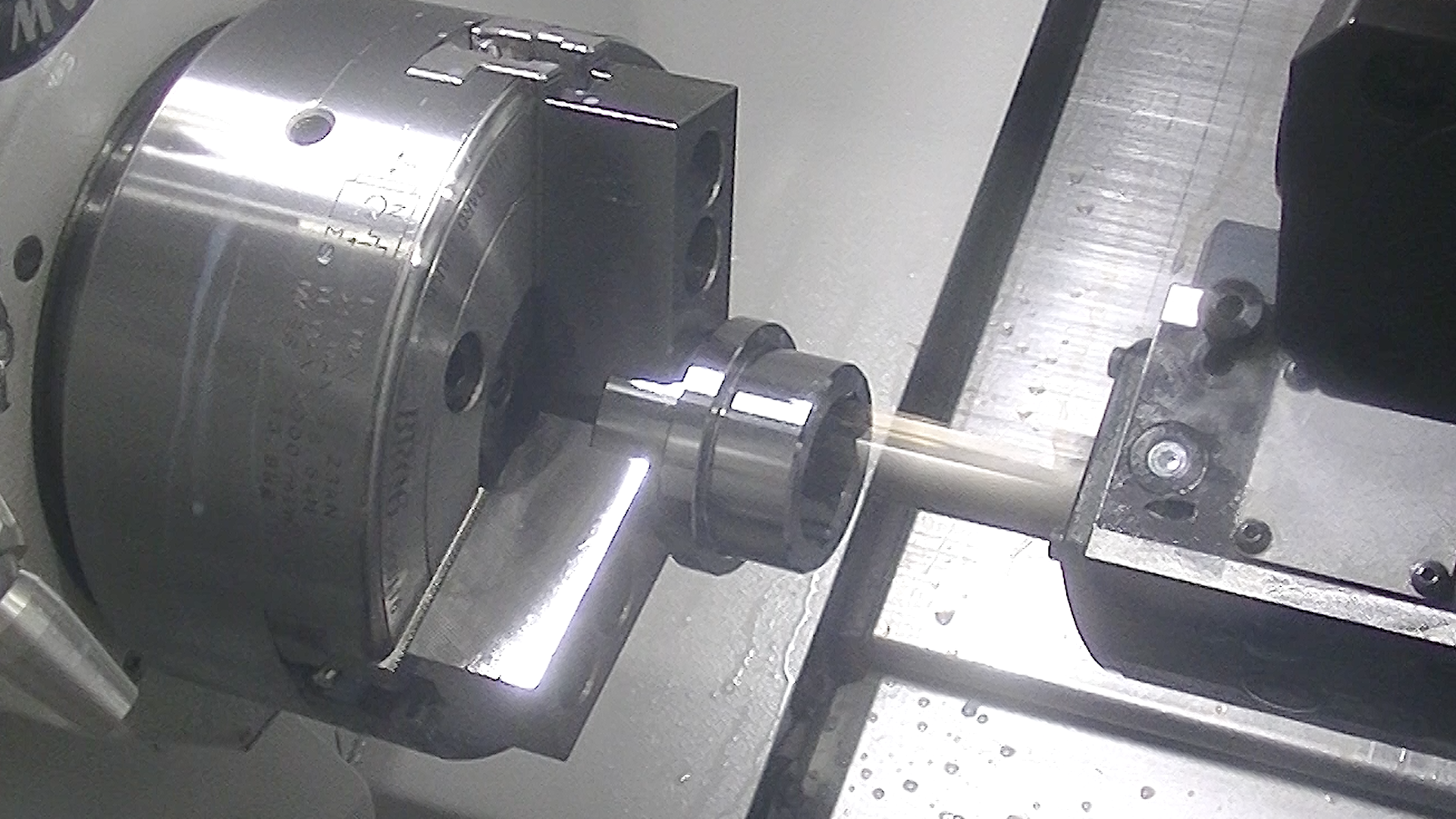

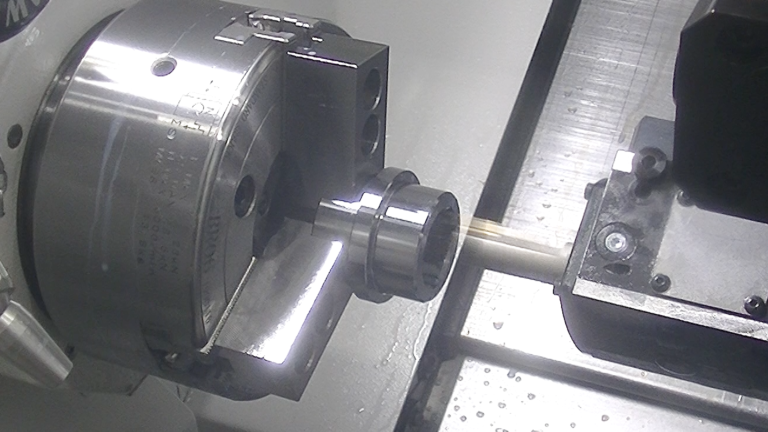

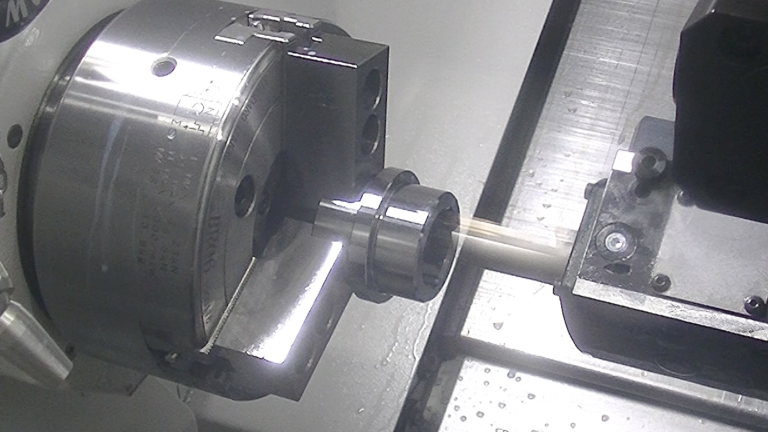

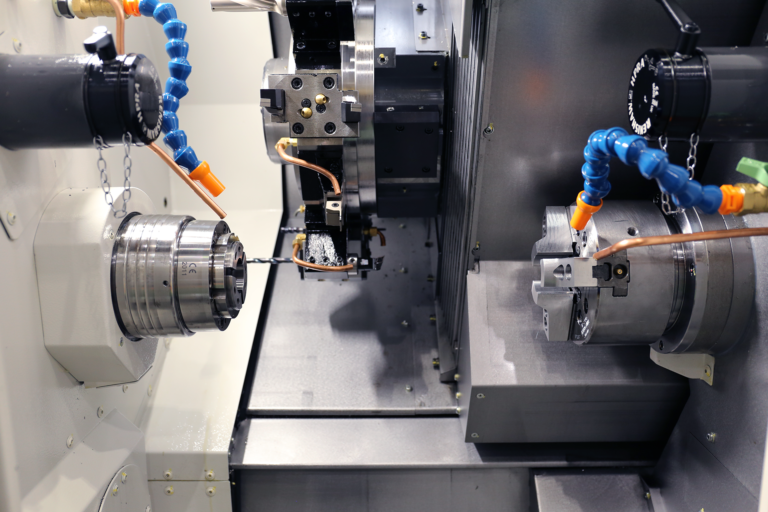

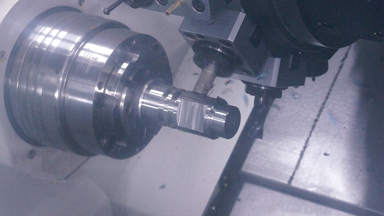

By moving the tool back and forth like a woodpecker, the groove is machined. At this time, we used a single-turret machine called SC-100.

3. How does this work?

There is a question that we often receive. “How does this work?”

Especially those who like machines and tools are curious about how it is driven, and they ask us this question with great enthusiasm. (We understand your feeling very, very well.)

Actually, this movement is achieved by converting the turret rotation mechanism used in milling into linear motion in the holder. The person who made this was definitely open-minded.

This allows for special machining to be done with a standard machine.

4. Summary

It was very interesting to see how well the tool and machine collaborated to create a new area of complex machining. We hope to introduce more examples of exciting machining tools and methods, in collaboration with multitasking machines like this one!!