Machining Support

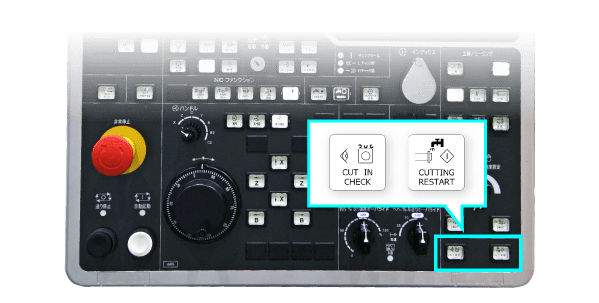

Machining Check Function (CUT IN CHECK)

This function allows you to temporarily pause or resume the machining process at the press of a button when you need to stop the machine in the middle of the processing.

You can temporarily pause the machining program when creating the initial parts, in case the chips unexpectedly tangle or when there's an unusual noise from the machines.

You can temporarily pause the machining program when creating the initial parts, in case the chips unexpectedly tangle or when there's an unusual noise from the machines.

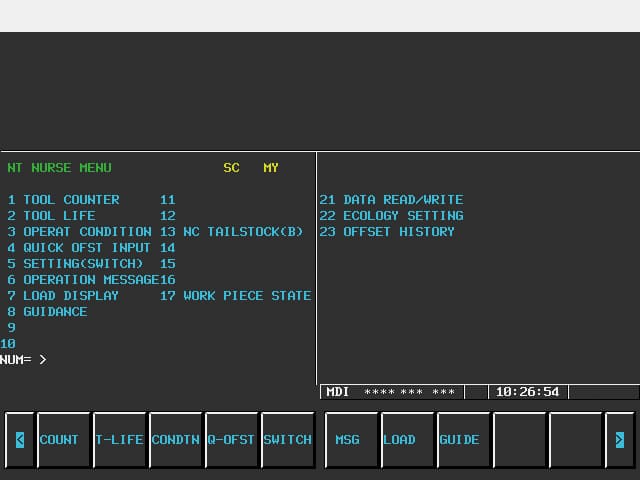

NT NURSE

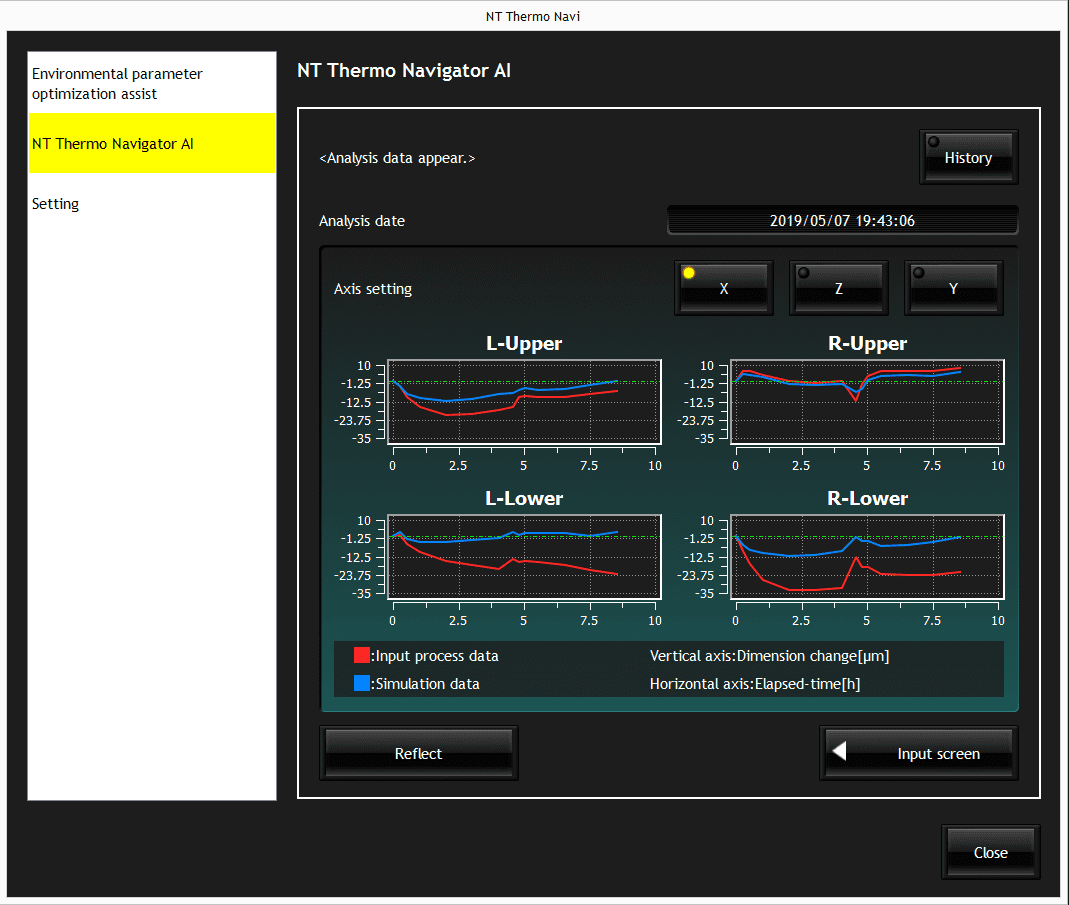

NT Thermo Navigator AI

This function enables the calculation of thermal growth compensation with high accuracy. AI builds an optimal thermal compensation value by simply entering time and measurement dimensions into the dedicated software.

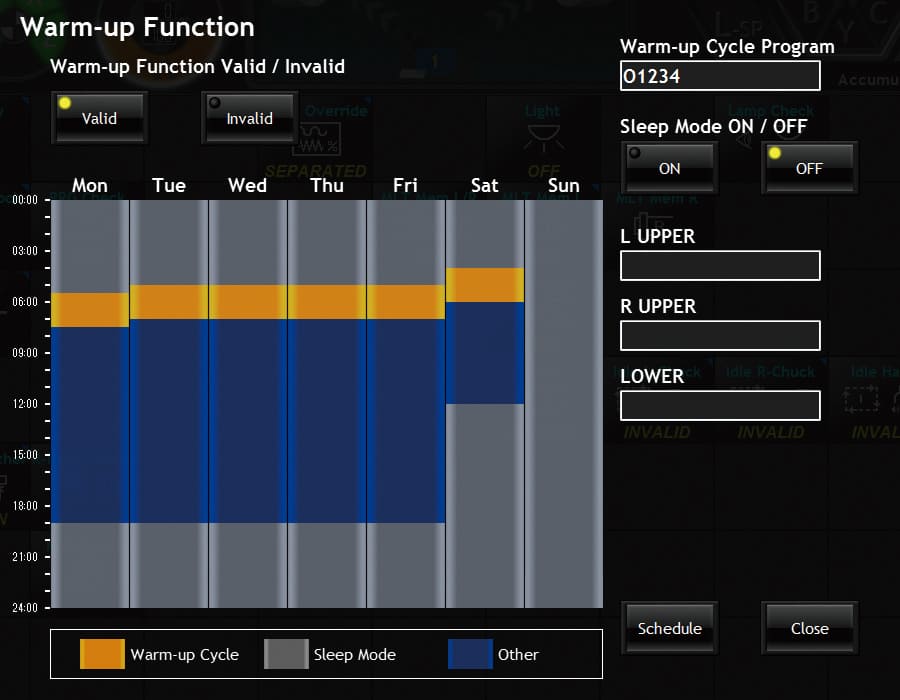

Warm-Up Function

NT WORK NAVIGATOR

This software recognizes the material position or phase by torque control of the servo motor. There is no need for positioning fixtures or special clamping devices.

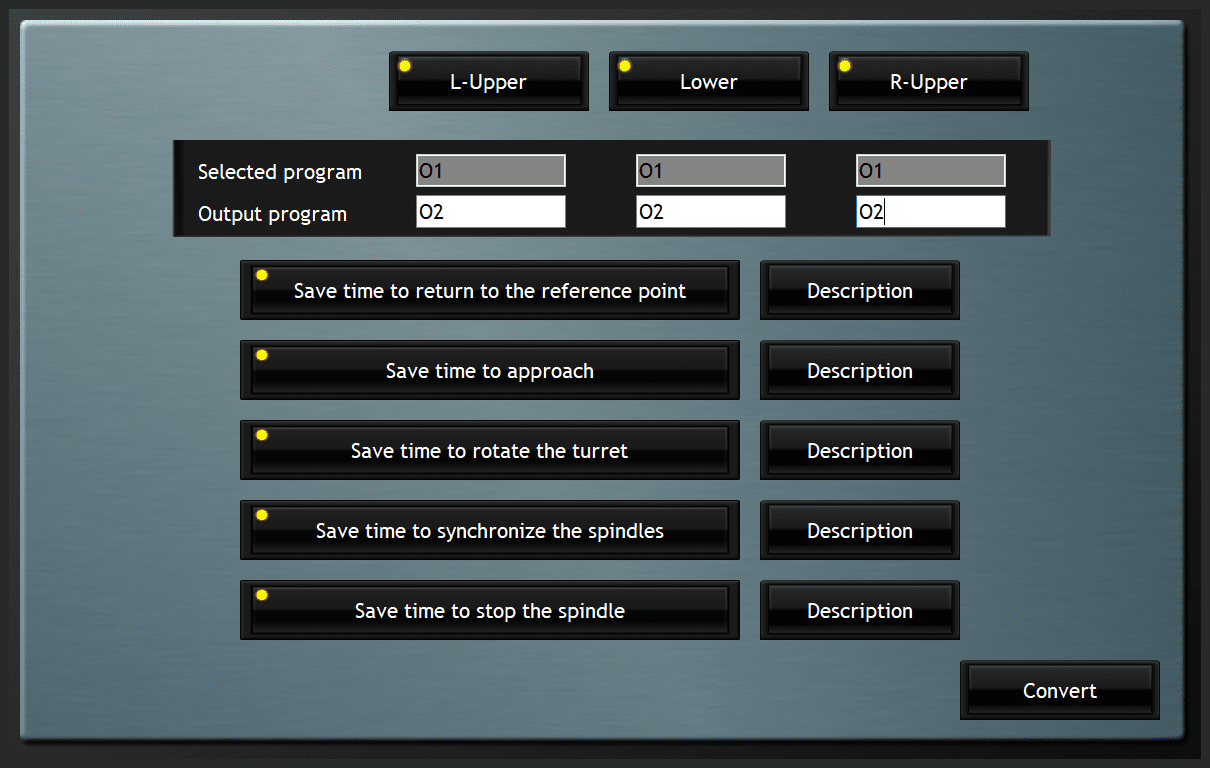

Program Optimizer

It optimizes NC programs to eliminate wasting idle time and reduce cycle time.

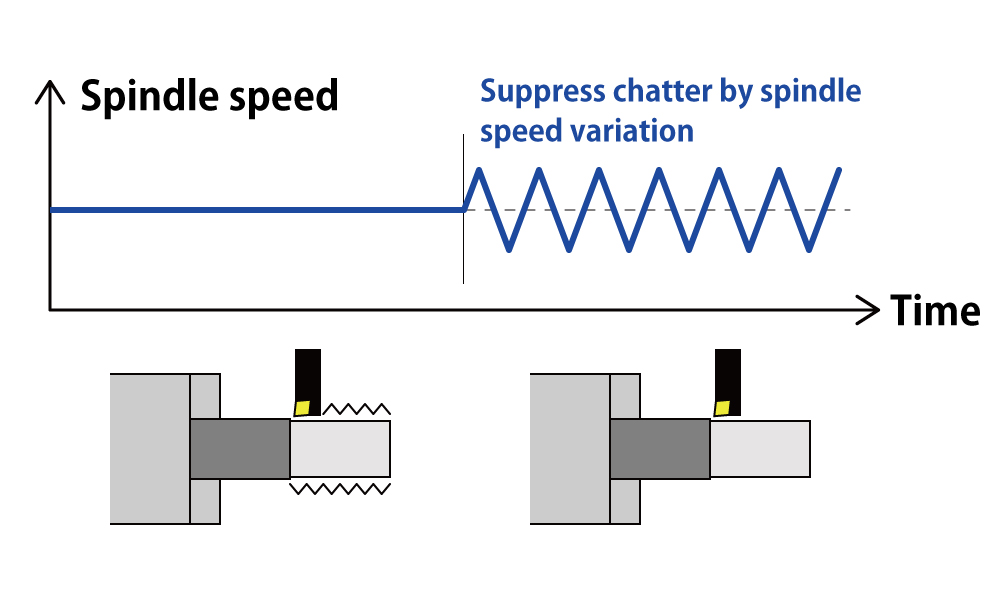

Chatter Canceller

By periodically accelerating and decelerating the spindle during machining, it supports chattering-free processing.

This function can be easily turned on by inserting M codes, and the spindle speed variation value (amplitude, frequency, waveform) can be set arbitrarily. It is also expected to reduce insert wear with this function.

This function can be easily turned on by inserting M codes, and the spindle speed variation value (amplitude, frequency, waveform) can be set arbitrarily. It is also expected to reduce insert wear with this function.

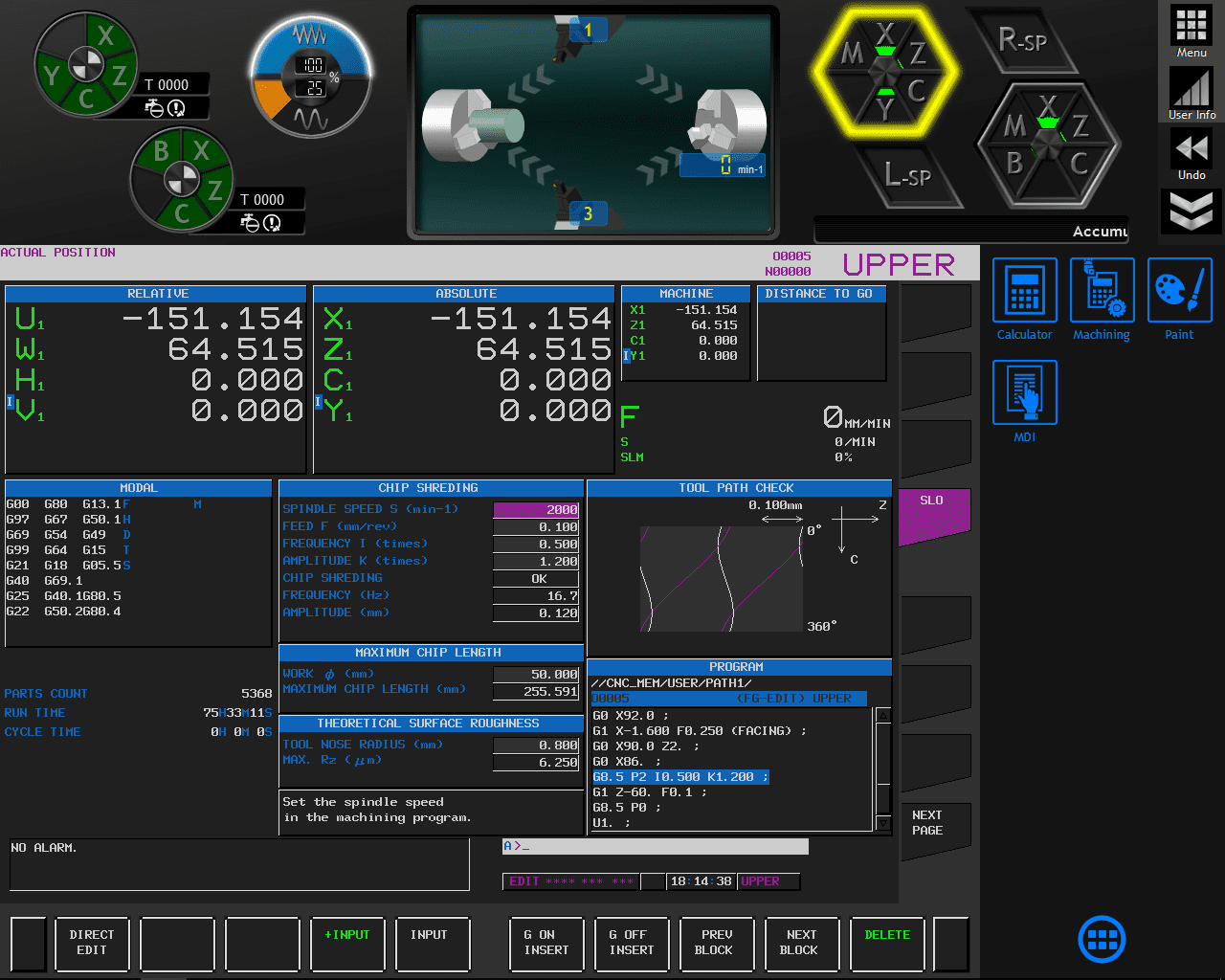

Oscillation Cutting

Oscillation Cutting can be activated easily by inserting a dedicated G code.

This function breaks chips into small pieces by oscillating the tool at regular intervals, solving the machine problem caused by long chips.

This function breaks chips into small pieces by oscillating the tool at regular intervals, solving the machine problem caused by long chips.

Smart Tuning

This software easily corrects geometric errors that arise due to aging or during precision machining requiring tight accuracy.

The corrections can be effortlessly made by attaching a reference ball and the HAN-BEI automatic measuring system. A total of 10 types of geometric errors, including the center position error of the tool spindle, can be modified, leading to accuracy improvements.

The corrections can be effortlessly made by attaching a reference ball and the HAN-BEI automatic measuring system. A total of 10 types of geometric errors, including the center position error of the tool spindle, can be modified, leading to accuracy improvements.