Setup Support

Setup Screen

All related statuses, including not only the tool management system showing a tool counter, spare tools, and load monitoring but also the systems related to the tool offset and workpiece coordinate, are integrated into a single screen, saving bothersome steps to search or switch screens when operators run multiple software simultaneously.

Simple Call

Icons of support functions frequently used by the operator are displayed together on the right side of the CNC screen for easy access. These icons are always displayed while the control panel screen is displayed, allowing operators to call up convenient functions with one touch at any time.

Moreover, One Touch MDi, which registers and calls NC fixed sentences, makes it easy to register a frequently used program block to register as a fixed form. It drastically reduces programming time.

Moreover, One Touch MDi, which registers and calls NC fixed sentences, makes it easy to register a frequently used program block to register as a fixed form. It drastically reduces programming time.

Digital Chuck Interlock

Geometry Navigator

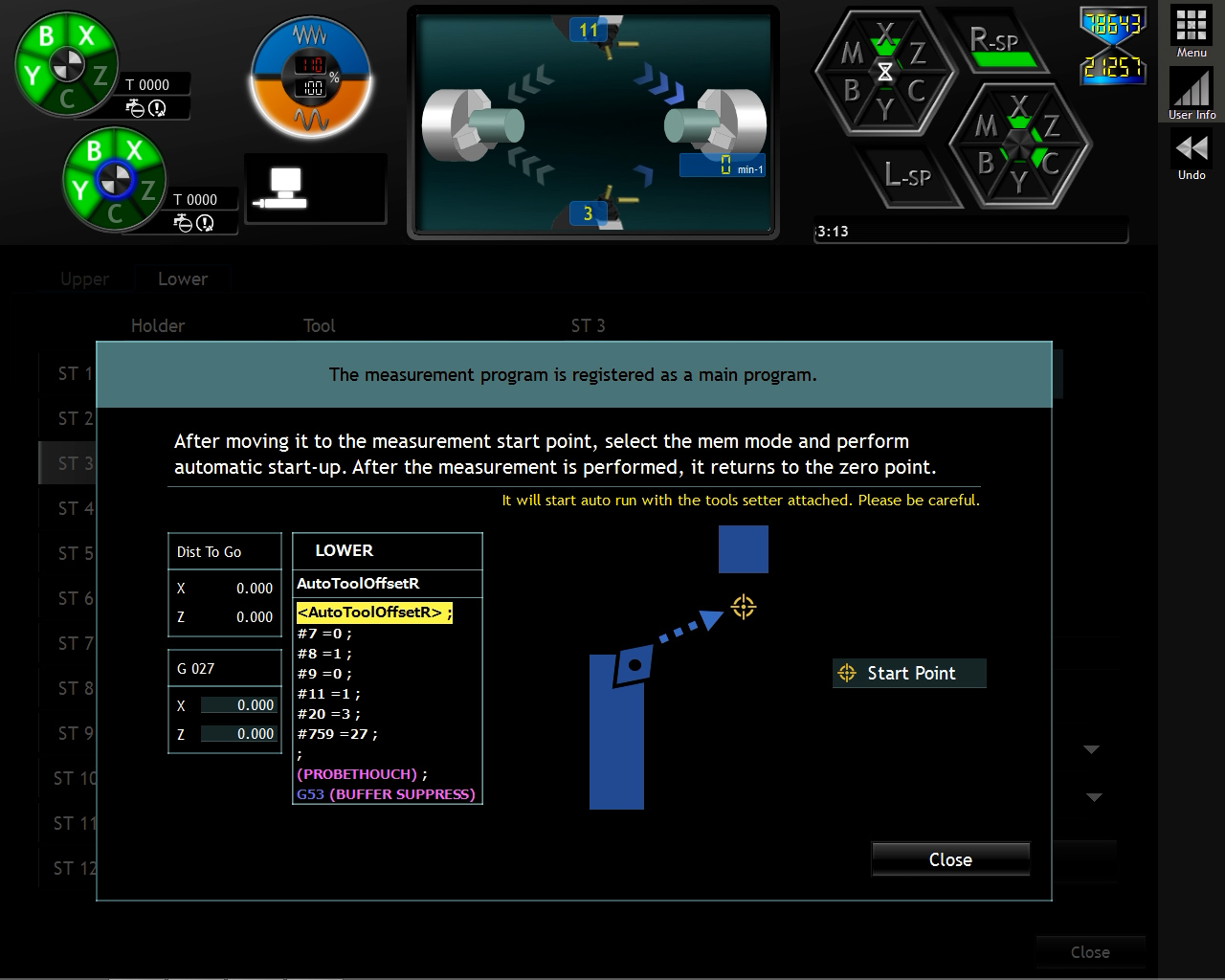

This is a support function that automates all measurement operations except the approach.

Guidance displays the procedure for taking geometry offset using the tool setter. With guidance, anyone can get the job done quickly and easily.

Guidance displays the procedure for taking geometry offset using the tool setter. With guidance, anyone can get the job done quickly and easily.

One Touch Production

After changing the insert, the measurement of the first workpiece is automatically adjusted even from the machine’s cold start. Since manual operation has been eliminated, operators are no longer required to stay beside a single machine and can work more efficiently.