Compact Meets Flexibility NT-Flex

Compact CNC Machine for Big Results

Is Your Shop Floor Facing Efficiency Challenges?

Limited Space for New CNC Machines and Machine Tools

Limited space makes it difficult to install new machine tools or rearrange your factory layout, but you still need to boost productivity with advanced CNC machines.

Time-Consuming Lathe Machine Setup During Frequent Changeovers

Frequent changeovers are needed, but lathe machine setup takes too much time, slowing down your workflow.

Complex Parts That Current Machine Tools Cannot Fully Process

Parts are becoming smaller and more complex, but your existing machine tools can’t finish them completely—precision CNC machining is essential.

NT-Flex is the solution

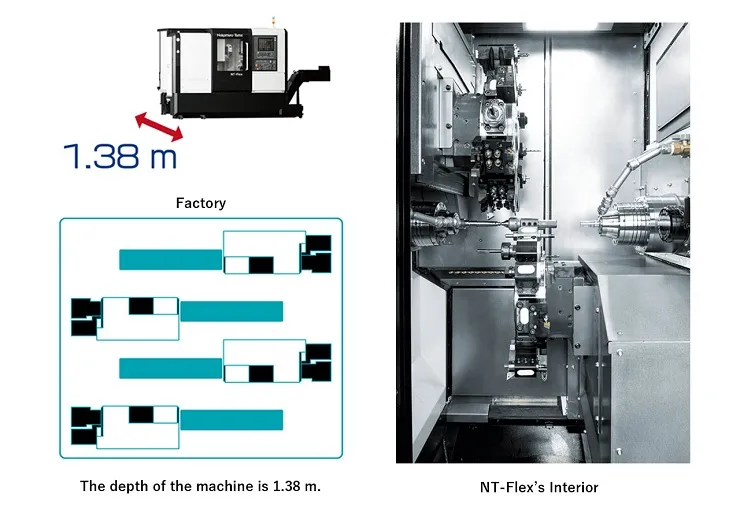

With a footprint of just 1.38 meters in depth — this compact CNC machine completes all processes in one setup.

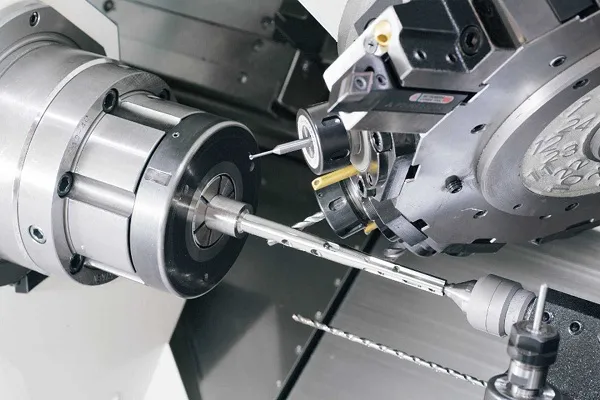

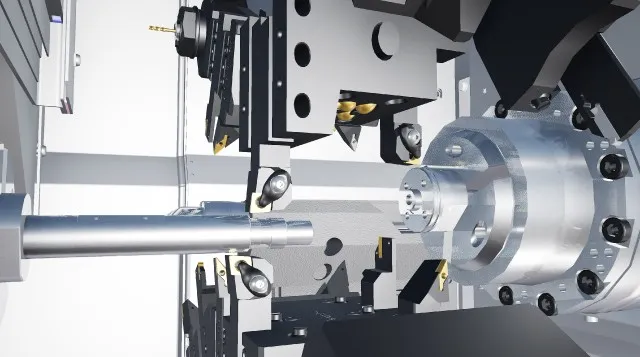

NT-Flex is a precision multitasking CNC lathe machine with 2 spindles and 2 turrets, designed to maximize the use of limited factory floor space without any wasted gaps. Featuring a standard milling function and Y-axis on the upper turret, this compact machine tool can efficiently handle machining for over 100 different product types, helping your production meet diverse customer demands.

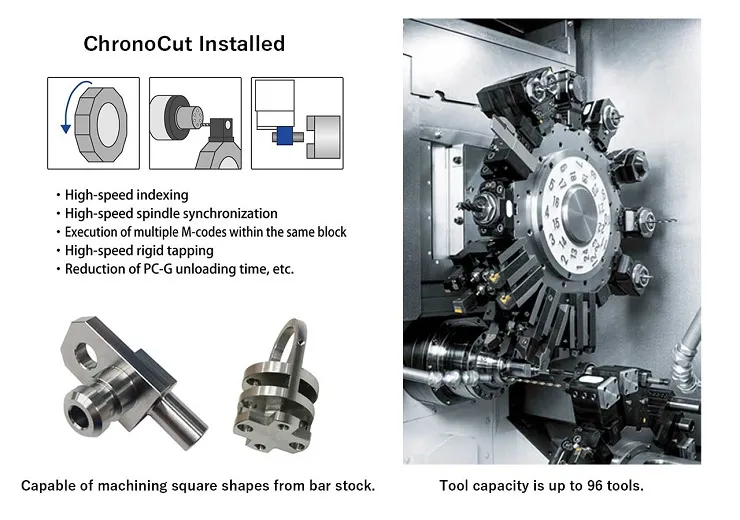

Equipped with up to 96 tools! NT-Flex meets the diverse needs of increasingly complex workpieces.

Despite its compact size, this CNC machine features two 24-station turrets—one upper and one lower. By using quadruple holders, it can accommodate up to 96 tools. This single machine tool handles all machining processes, including turning, milling, and gear cutting.

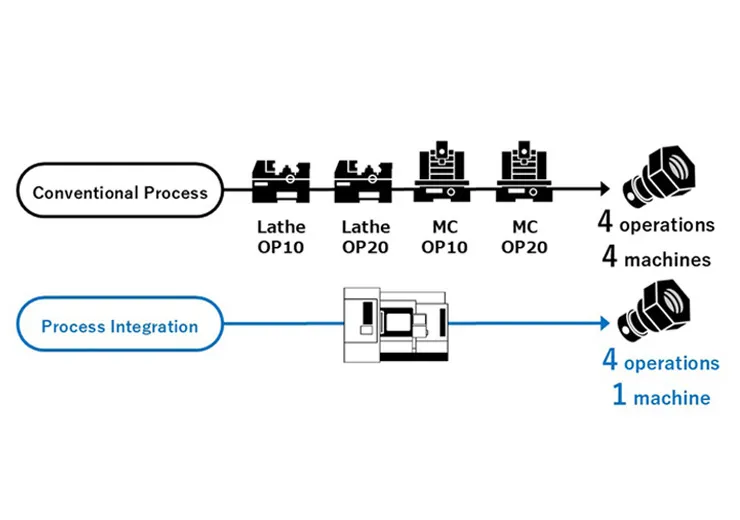

Combining multiple processes boosts efficiency and cuts costs.

A multitasking machine enables process integration, allowing multiple machining steps to be done on a single CNC machine instead of separate machining centers. This reduces inventory and labor costs, saves space, and streamlines production.

Specifications

| φ32mm | φ38mm(op.) | |

|---|---|---|

| Max. Turning Diameter | φ150mm | φ150mm |

| Max. Turning Length | 250mm | 250mm |

| Distance Between Spindles | max.655mm/min.200mm | max.655mm/min.200mm |

| Bar Capacity | 32mm | 38mm |

| Chuck Size | 5″ | 5″ |

| L/R Spindle Speed | 8,000min-1 | 8,000min-1 |

| L/R Spindle Drive Motor | 7.5/5.5kW | 7.5/5.5kW |

| Floor space | height:2,010mm/width:3,500mm/depth:1,380mm | height:2,010mm/width:3,500mm/depth:1,380mm |

NT-Flex+ specification(op.)

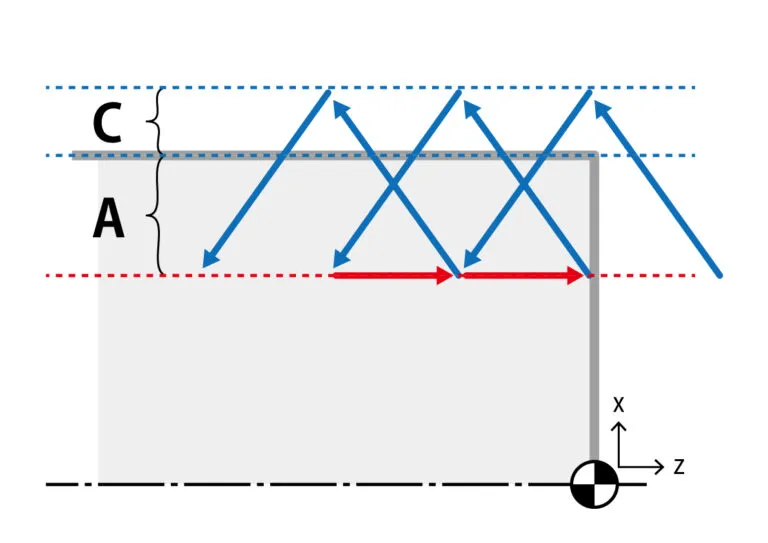

“NT-Flex+” is a new specification of the NT-Flex, featuring X-axis travel on the R-spindle and an optional NC tailstock. It also adds Y-axis travel to the lower turret, enabling support for more complex machining patterns, such as superimposed machining with three tools operating simultaneously.

Oscillating Cutting & Triangle Cut(op.)

NT-Flex is equipped with Oscillation Cutting(*) as standard to improve chip evacuation and offers the optional Triangle Cut feature for enhanced chip control. *Oscillating Cutting is available on the Z-axis only.

Related Videos

-

Produce 100 Types of Parts with a Compact 1.38m Depth Machine: NT-Flex!

-

Semiconductor Parts Machining with Compact 1.38m Multitasking Machine 「NT-Flex」

-

EV Motor Shaft Parts Machining with Compact 1.38m Multitasking Machine 「NT-Flex」

-

EV Motor Shaft Parts Machining with Compact 1.38m Multitasking Machine 「NT-Flex」

Frequently Asked Questions

-

What are the benefits of introducing a multitasking machine?

By introducing a multitasking machine, multiple processes can be completed on a single machine instead of separate lathe machines or other machine tools. This eliminates the need for setup changes and workpiece transfers between different machines, significantly improving overall operational efficiency. Since the entire process is completed in one cycle, machining accuracy remains consistent, leading to higher product quality. Moreover, with fewer machine tools required, your factory layout can be optimized, making better use of available floor space. In short, multitasking CNC machines help streamline production, enhance precision, and optimize resource allocation, resulting in more efficient and flexible manufacturing. In short, multitasking machines help streamline production, enhance precision, and optimize resource allocation, resulting in more efficient and flexible manufacturing.

-

What types of components are best suited for multitasking machines?

Multitasking machines are especially suitable for complex-shaped parts and shaft-type components. Because these machine tools can perform both turning and milling in a single setup, they are ideal for producing high-precision parts. They are also well-suited for small-lot production where frequent product changeovers are required. Thanks to simplified setup processes, multitasking machine tools offer great flexibility and productivity in high-mix, low-volume manufacturing environments.

-

What preparations are needed before introducing a multitasking machine?

The first step in introducing a multitasking machine is to clearly define the size, shape, and material of the parts to be machined. Next, it is important to prepare the installation environment, including checking the available floor space, power supply, and floor load capacity. It is also essential to plan training in advance so that operators can learn how to use the CNC machine and acquire the necessary programming skills. Additionally, considering the introduction and effective use of CAD/CAM software will help streamline the creation of machining programs and enhance overall productivity.

-

Are the machine operation and maintenance difficult?

Operating and maintaining a multitasking machine requires some initial training, but rest assured — the experienced staff of our authorized distributors will provide thorough guidance during installation to ensure a smooth start.

Start by downloading our free product catalog.

Recommended for:

- Manufacturers in urban areas or small to mid-sized factories, where floor space is always a limiting factor.

- Those handling more custom orders or made-to-order production and need greater flexibility in operations.

- Companies experiencing missed opportunities due to sudden orders or design changes they can’t respond to quickly enough.

CNC Machine Lineup

ATC Multitasking Machine

Swiveling B-Axis Turret

Multi-Turret Machine

Single-Turret Machine

Automation Lineup

Gantry Loader

Built-in Automation

Robot System