Medical

Shoulder Implant

- Titanium Ti-6AI-4V

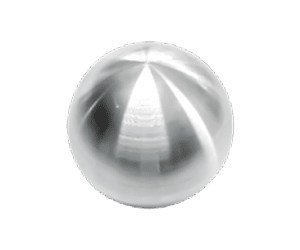

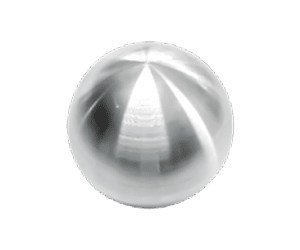

Metal Head

- φ28 CoCrMo

Femur Support

- φ22×220L

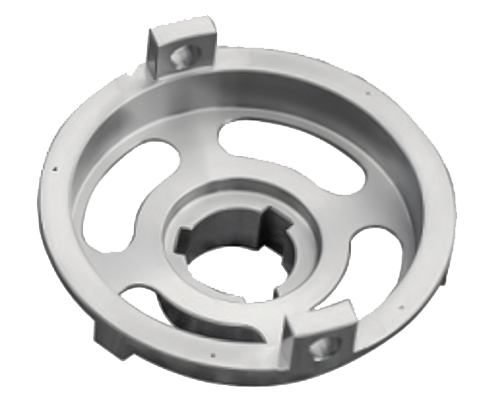

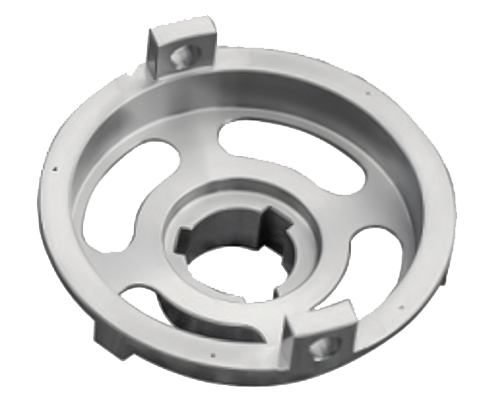

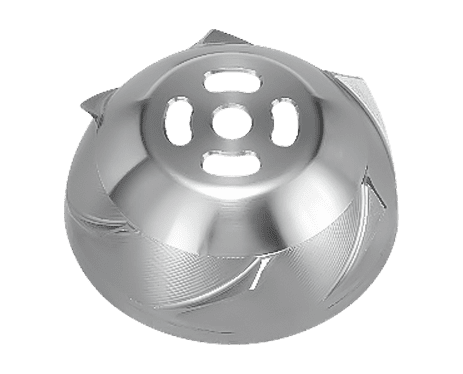

Hip Cup

- φ45 Bar material β-Titanium

Artificial Knee Joint

- φ70×100L Titanium Ti-6AI-4V(Grade 5)

Microscope Part

- φ30 Bar material SUS303

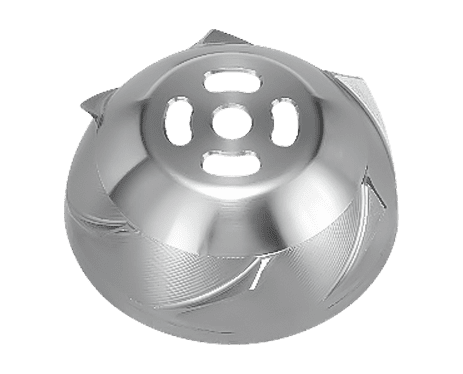

Artificial Heart Pump

- φ40×500L β-Titanium

Endoscope

- φ65 Bar material SUS303

Bone Screw

- φ23

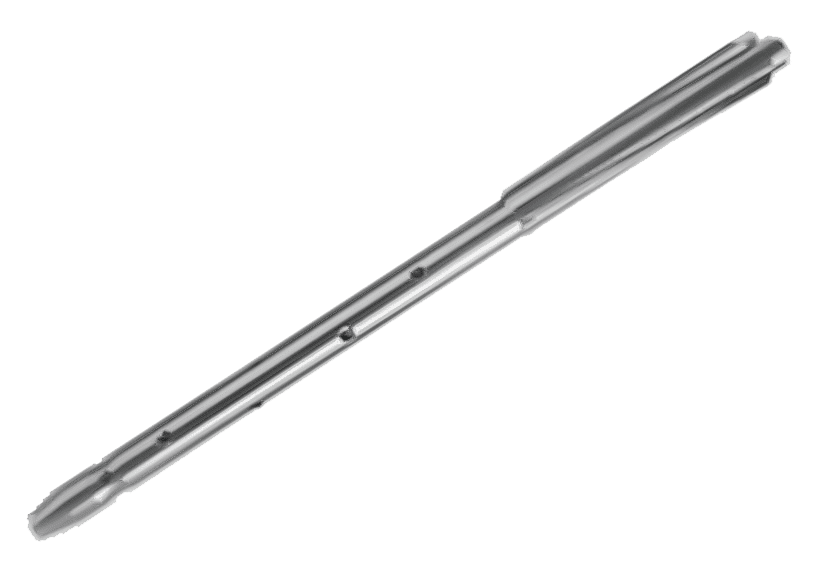

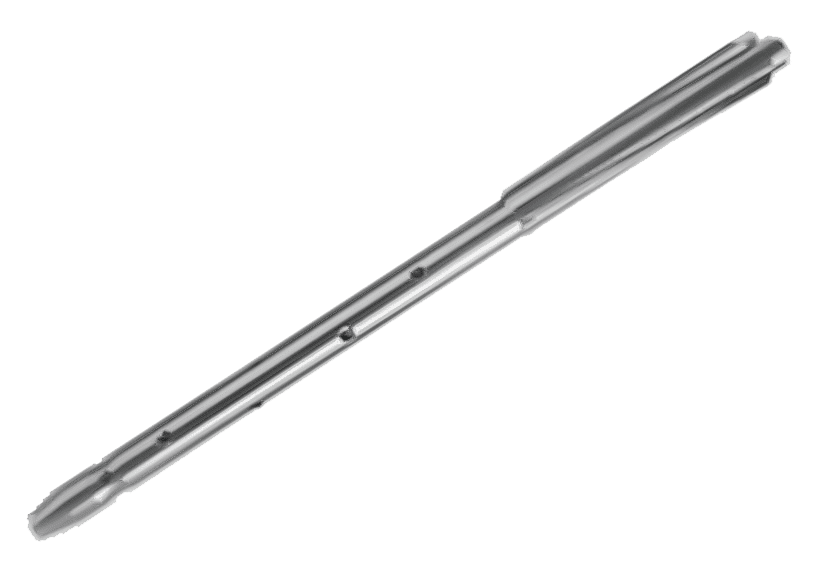

Intramedullary Rod

- φ16

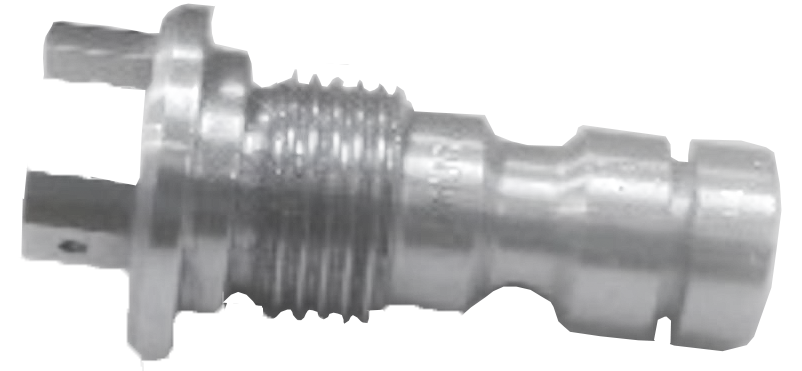

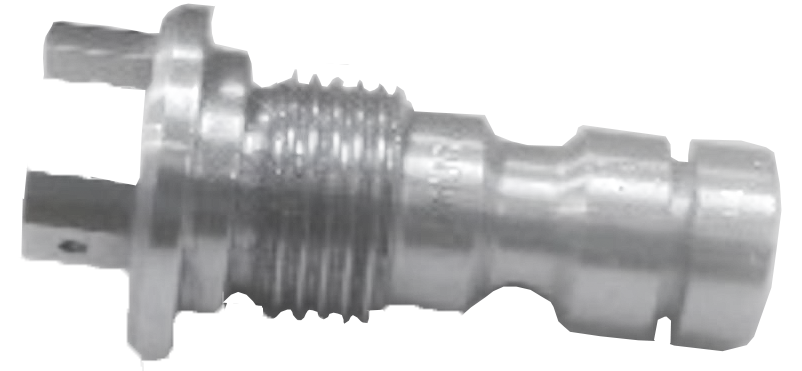

Connector

- φ25×50L SUS303

| Material | Titanium Ti-6AI-4V |

Point In the mass production of medical components, high-efficiency angled hole machining using a B-axis turret has been achieved.

Click to play video

| Diameter | φ28 |

| Material | CoCrMo |

Point High-precision machining has been achieved, successfully controlling sphericity to within 5μm and surface roughness (Ra) to approximately 0.2μm in continuous machining.

| Diameter | φ45 |

| Material | Bar material β-Titanium |

Point Complete processing from bar material to finished product can be done with a single machine.

Click to play video

| Diameter | φ70×100L |

| Material | Titanium Ti-6AI-4V(Grade 5) |

Point The milling of knee joints and the customization of shapes to fit patients have been achieved through CAM software.

Click to play video

| Diameter | φ40×500L |

| Material | β-Titanium |

Point By having the three turrets perform simultaneous machining operations, high-efficiency processing has been achieved, resulting in significant cycle time reduction. This has enabled production from bar material to finished products.

Click to play video