Many workshops still rely on manually operated machine tools such as conventional lathes and milling machines. However, because it’s difficult to machine identical parts with high precision, these machines aren’t suitable for mass production—and they often require highly skilled operators. For these reasons, automation technologies that handle a wider range of machining tasks have advanced rapidly in recent years.

In this article, we’ll explore the benefits that machine‑tool automation can bring to your shop floor and take a look at the kinds of operations that can actually be automated.

1. WHAT IS MACHINE TOOL AUTOMATION?

Machine tool automation refers to creating a system in which the machine—together with peripheral equipment such as loaders or robots—takes over part or all of the machining process in place of a human operator. By doing so, the machine can carry out work more consistently and efficiently, ultimately boosting overall productivity.

2. WHY MACHINE TOOL AUTOMATION IS BECOMING ESSENTIAL

Lack of skilled workers across the entire manufacturing industry

As technology continues to transform the manufacturing industry, the demand for people with specialized skills keeps rising. However, many workers still lack the training and need education to take on these roles. The situation has become even more challenging as large numbers of skilled technicians retire. In addition, fewer young people are choosing careers in these fields. As a result, the shortage of skilled labor continues to deepen across the industry.

Operators are overworked

In the manufacturing industry, the recent trend has been towards high-mix, low-volume production. This shift has led to increased setup changes for processing, requiring operators to spend long hours attaching/detaching workpieces or checking dimensional accuracy. This issue needs to be addressed as it burdens operators.

Reinforcing production and competitiveness

Installing automation equipment enables machines to perform machining tasks late at night when it is difficult to secure operators, resulting in enhanced productivity. Many companies aim to improve their production and competitiveness through automation.

3. BENEFITS AND DRAWBACKS OF AUTOMATION

Automation of machine tools enables the processing of complex-shaped parts and high-precision machining, which are difficult to achieve manually. Proper automation systems offer benefits in various work conditions.

Benefits

Streamlining the production line workforce while addressing the labor shortage

Automated processes eliminate the need to assign workers to tasks, thereby reducing labor on the production line. This also addresses labor shortages, and if all processes can be automated.

Improving and stabilizing quality

Manual operation is not stable and can lead to mistakes. Automation can eliminate these problems and ensure consistent product quality.

Reduced labor costs

Labor costs can be reduced because machines can operate continuously without the need for additional operators. In recent years, the development of machine tools equipped with AI has progressed, which is a significant advantage as it reduces not only costs but also the burden of on-site work.

Free time for other tasks

By automating manual processes, time can be freed up for other tasks. If you are struggling with being too busy to complete other tasks, you can solve this problem by introducing automation instead of hiring additional operators.

Drawbacks

High initial cost

The initial cost of implementing automation system can be expensive, varying based on the peripheral equipment to be integrated. Nevertheless, automation offers numerous benefits and is anticipated to deliver greater value than its cost.

Costly to maintain and manage

Automating and running machines for 24 hours incurs significant daily costs for electricity and maintenance. It’s important to consider not only the initial cost but also the ongoing maintenance and management expenses when implementing such a system.

4. EXAMPLES OF PROCESSES THAT CAN ACTUALLY BE AUTOMATED

Parts transfer

Manually loading and unloading heavy workpieces to and from the machines is both time-consuming and extremely dangerous. By automating these tasks, you can operate your machine safely and efficiently.

【Equipment for automation or subject to be automated】

- ・Gantry loader

- ・Work stocker

- ・Bar feeder

- ・Articulated robot

- ・Shaft loader, etc.

Parts loading and unloading

The loading of materials and unloading of finished products can be automated. By implementing automation equipment, loading and unloading of workpieces can be performed consistently and efficiently without the quality of the work depending on the operator.

【Equipment for automation or subject to be automated】

- ・Articulated robot

- ・Loader/Unloader, etc.

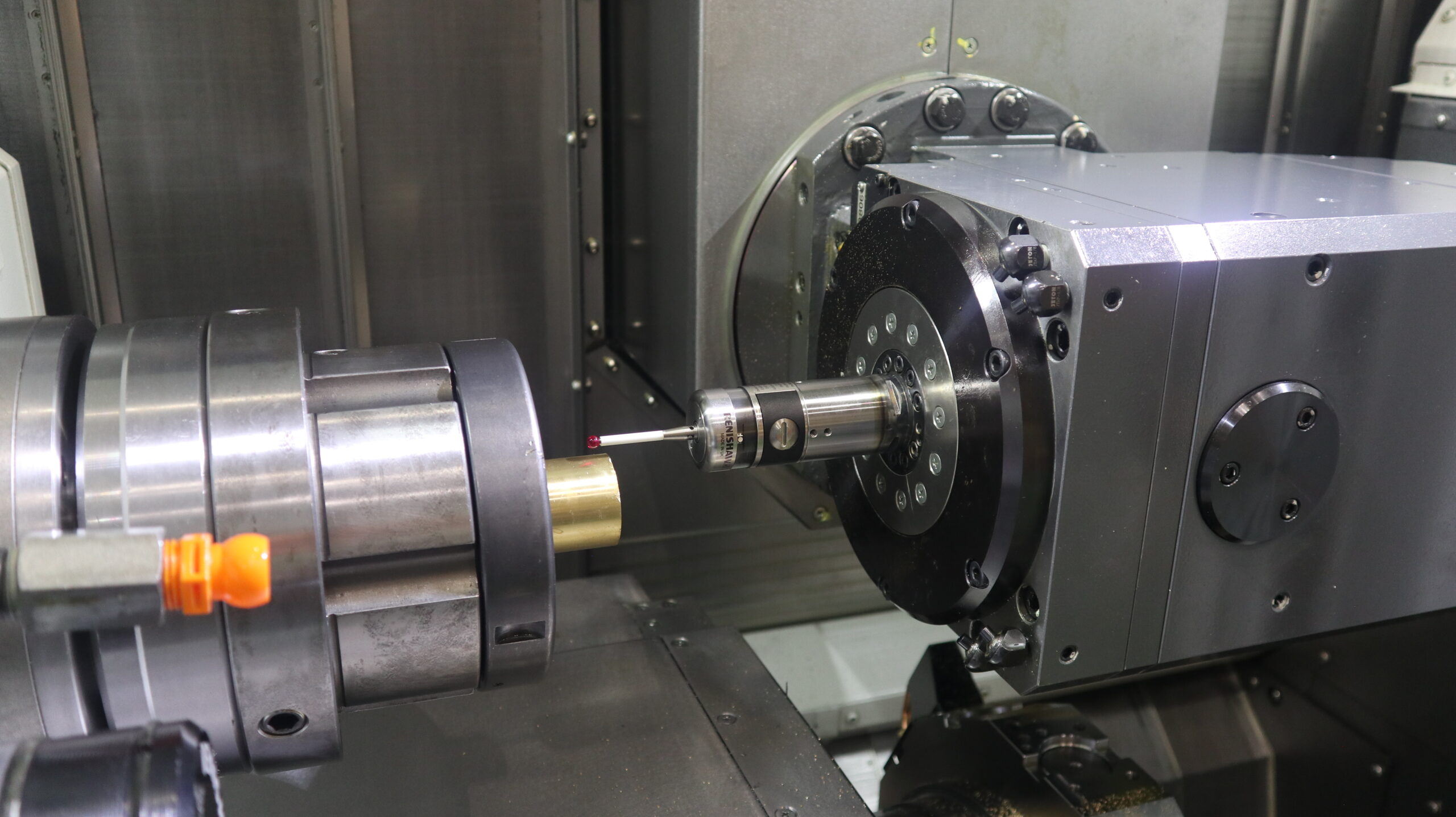

Inside and outside measurement

While measuring requires a skilled operator, there are machines available for automating the measurement of workpieces. Some machines measure workpieces internally, while others measure them externally after removing finished products using a gantry loader or similar equipment, and then automatically transfer them to a stocker. This process helps stabilize product dimensions and supports automated operations

【Equipment for automation or subject to be automated】

- ・Touch probe

- ・Gantry loader, etc.

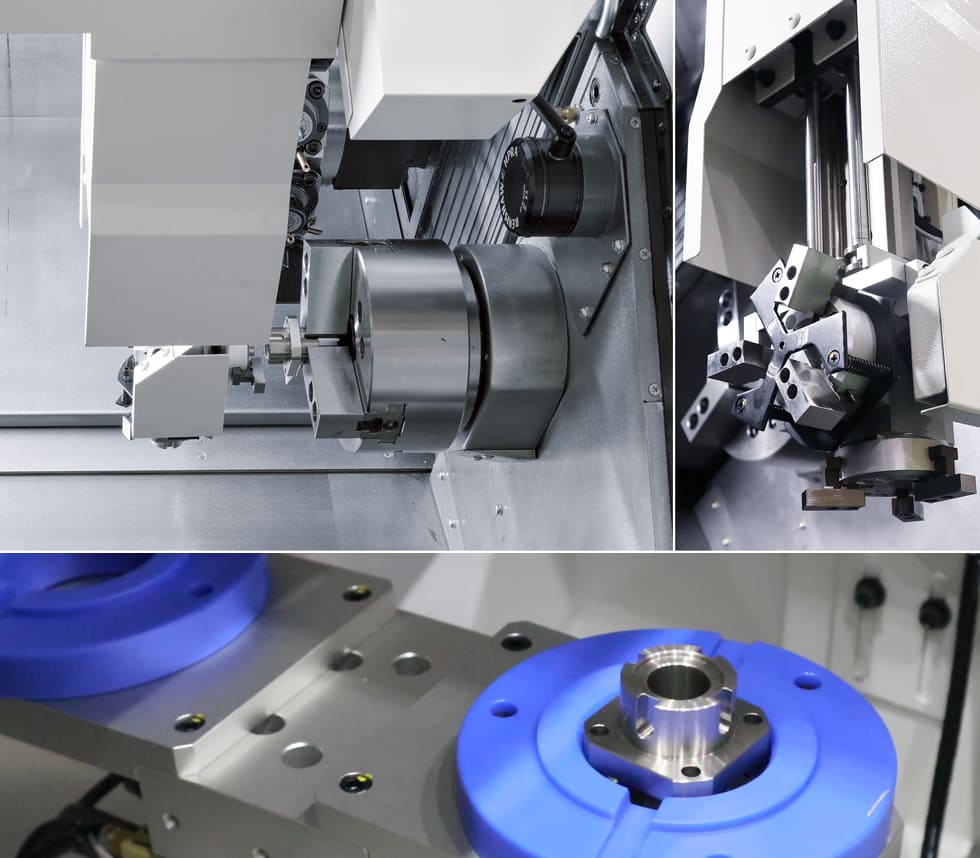

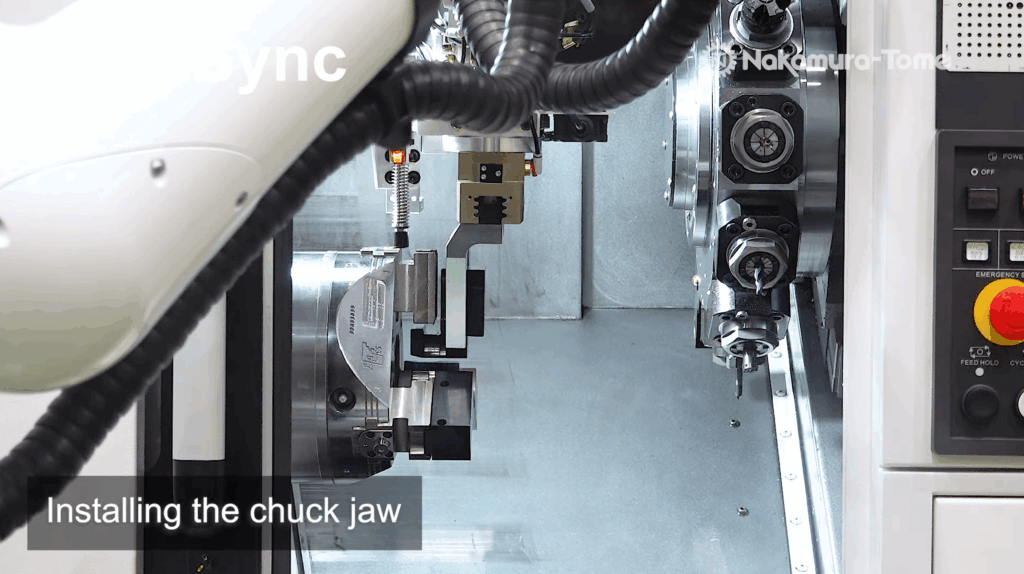

Change of chuck jaws

Changes of chuck jaws in setup operations are usually performed manually with tools, which makes unmanned operation difficult. Automation of jaw change facilitates unmanned nighttime operation and ensures continuous uptime.

【Equipment for automation or subject to be automated】

- ・Articulated robot

- ・Built-in transfer device, etc.

Programming

Creating machining programs using numerically controlled machine tools can be challenging for inexperienced engineers. However, if dedicated software is used for programming, the process can be automated, significantly reducing man-hours.

【Equipment for automation】

- Original software developed by each machine tool manufacturer

- CAD maker software, etc.

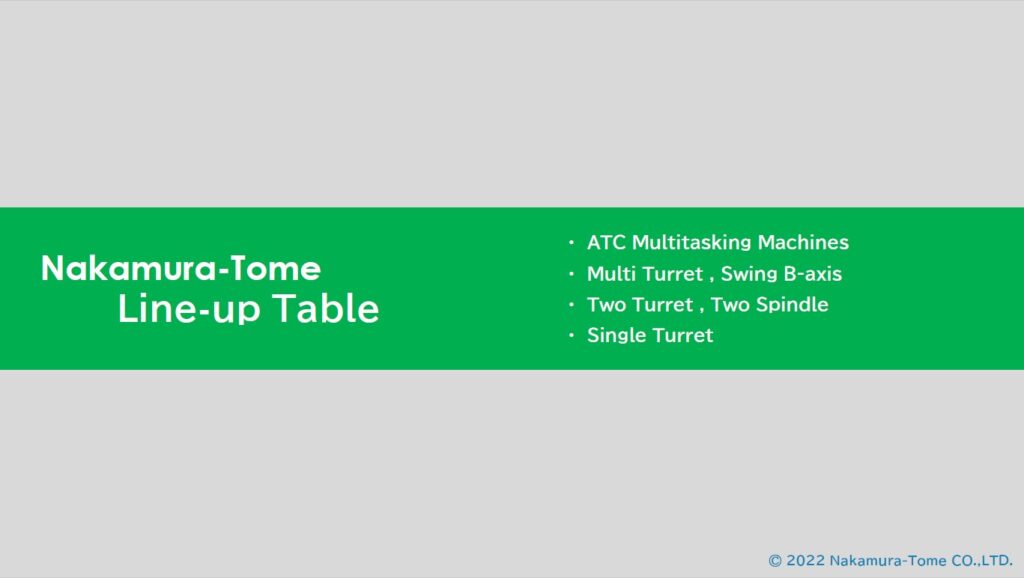

5. AUTOMATION FOR MULTITASKING MACHINES

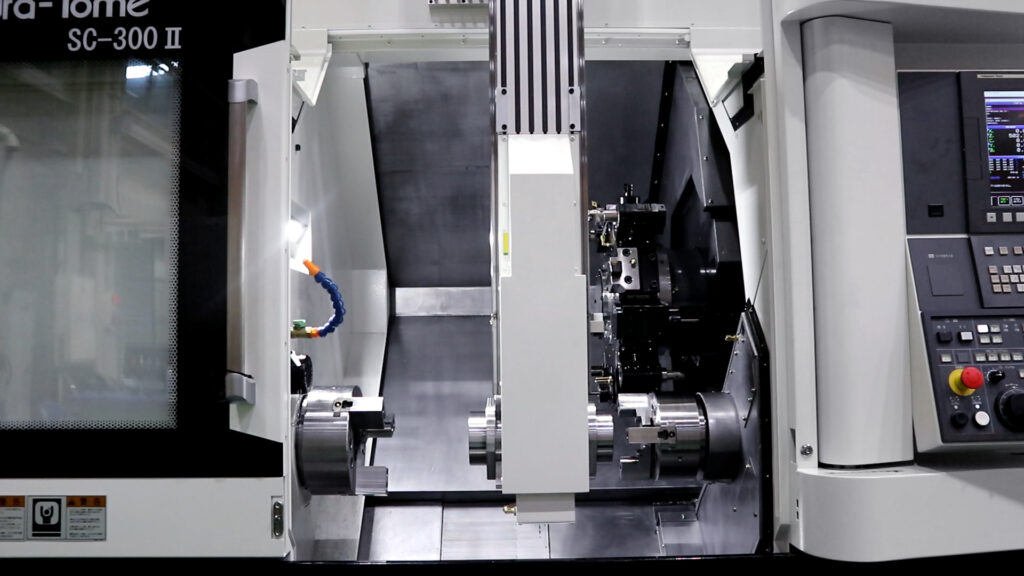

A multitasking machine is a machine tool capable of performing turning, milling, and other complex machining operations on a single machine, enabling the machining of blank materials into finished products.

In recent years, the manufacturing industry has increasingly pursued high-mix, low-volume (small-lot) production to flexibly respond to various processing requirements. There is also a growing demand for automation in parts processing.

Nakamura-Tome Precision Industry develops products to meet the automation requirements of multitasking machines. To learn more about our multitasking machines and automation products, please click below.

More information on automation products

6. CONCLUSION

Against the backdrop that many companies in the manufacturing industry experiencing labor shortages, there are high expectations for the development of automated systems for machine tools, which has attracted attention from the global market.

There are numerous benefits that companies can derive from enhancing productivity in the field through automation, such as having more time to focus on novel or diverse tasks. Please consider implementing automation system based on the manufacturing site’s environment and cost.