-

Cutting Tool Life: How to Measure, Maintain & Extend It

Understand the essentials of tool life—why it matters, how to measure it, and practical ways to extend it. This article explains wear mechanisms, maintenance strategies, and industry‑specific challenges, offering clear tips to improve machining accuracy, reduce costs, and boost overall productivity.

-

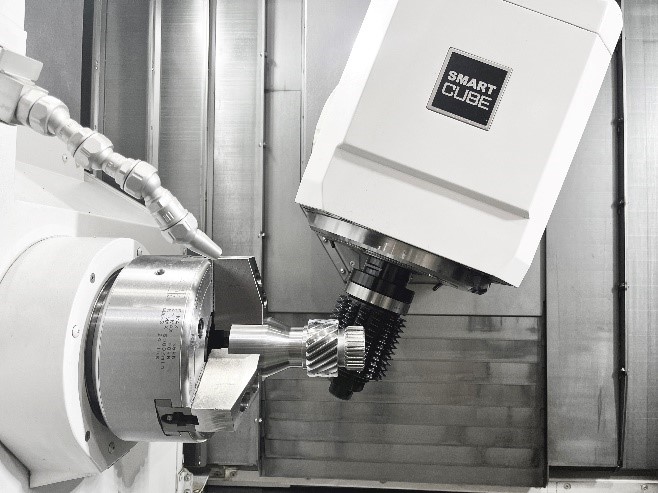

Make Gear Cutting More Efficient with CNC Multitasking Machines!

This article introduces the latest gear machining methods enabled by multitasking machines. Traditionally requiring multiple separate processes, gear production can now be completed on a single machine using techniques such as hobbing, skiving, and forming methods—significantly improving productivity and reducing setup time.

-

Unlock the Secrets Behind Gear Types and Shapes

This article introduces the fundamentals of gear design and explains what different gear shapes mean. It covers common gear types—such as spur, helical, bevel, internal gears, rack‑and‑pinion systems, and worm gears—and breaks down how each shape influences motion, direction, noise, efficiency, and load capacity. You’ll also learn important concepts like reduction ratios, backlash, and self‑locking mechanisms, helping you understand how gear geometry directly affects performance in real‑world applications.

-

Guide to Thread Cutting with Processing Programs

The threads you see every day without much thought come in various types depending on where they are used, their purpose, and the materials they are made from. This time, we’ll explain about metal threads that are commonly machined through cutting processes

-

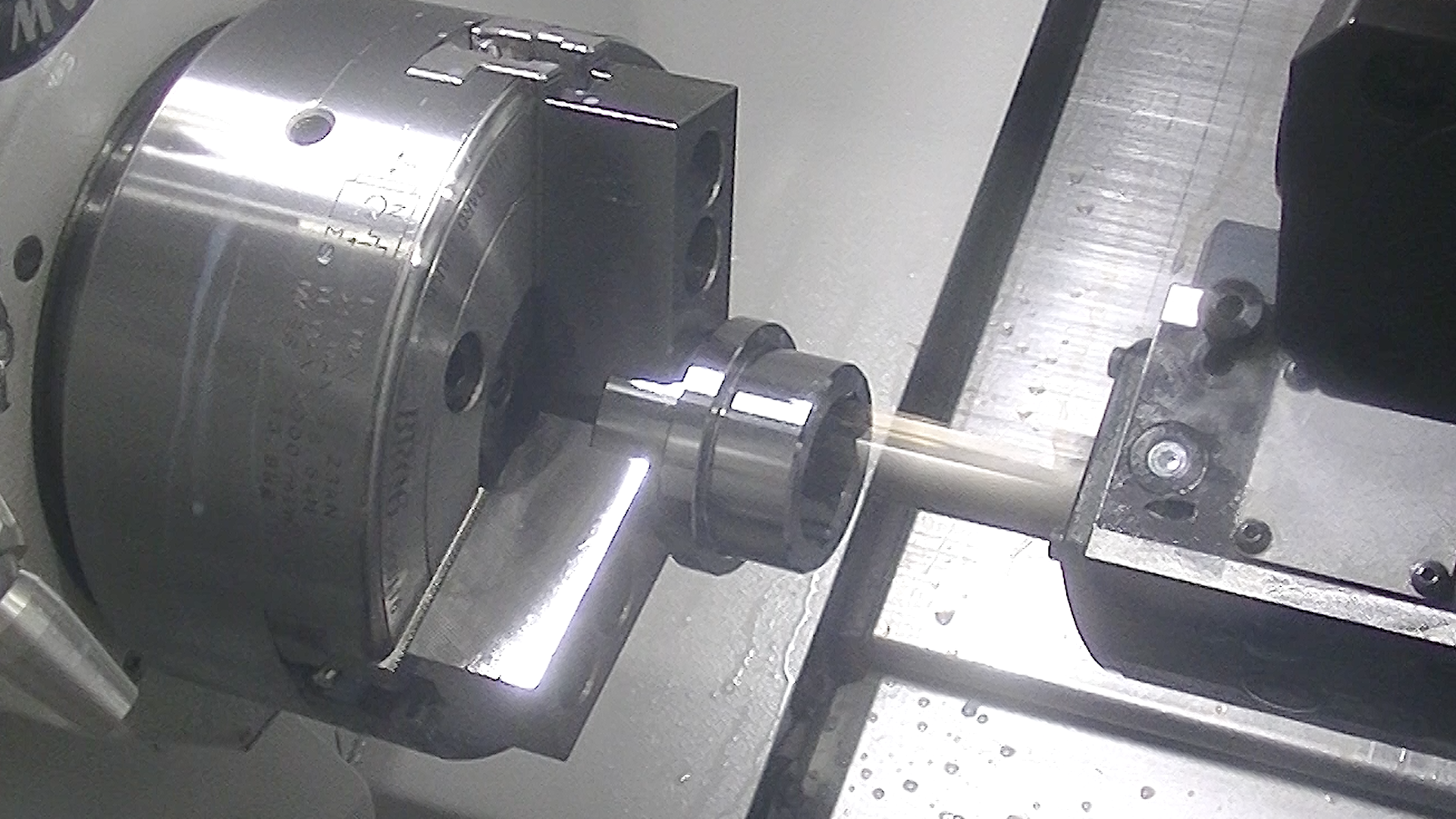

【CNC Lathe】Know-How for Reducing Cycle Time!

The cycle time per product is determined by the created NC program, but by reviewing and optimizing this program, the cycle time can be shortened. This article explains the key points of cycle time reduction that manufacturing engineers implement.

-

Machining Internal Keyway with Slotting Tool

Several methods exist for performing internal keyway milling, including using a slotting machine, a broaching machine, or an electrical discharge machine. However, a multitasking machine can also perform this operation. In this article, we will introduce keyway milling using a slotting tool with multitasking machines or lathes.

-

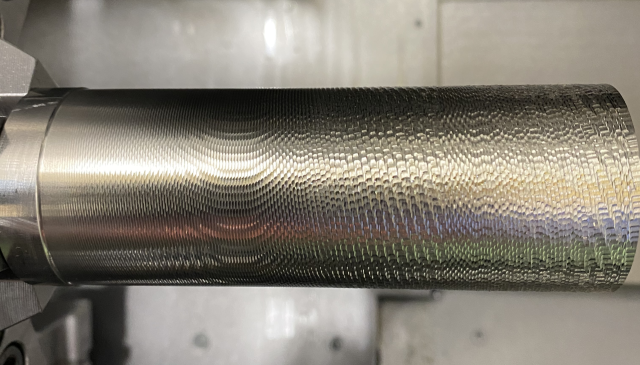

Cutting Chips in Machining: A Mine of Information!

When machining metals with machines like lathes or milling machines, various shapes of cutting chips (helical, ribbon, or broken) are generated. These chips reveal a lot through their color, shape, length, etc.

-

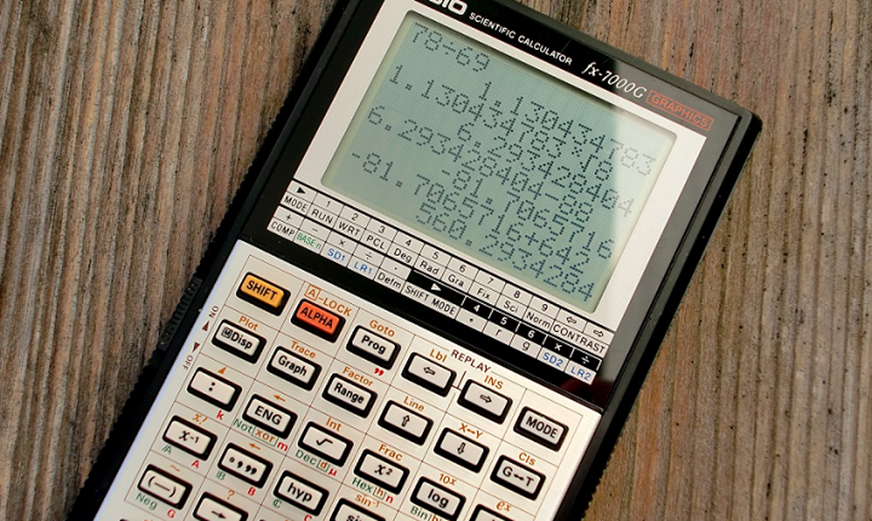

What Are Cutting Conditions? How Should They Be Determined?

To perform machining, a machine tool needs to have specified numerical values for cutting speed, rotation speed, feed rate, and depth of cut, which are referred to as cutting conditions (or machining conditions).

-

How Big Are the Nakamura-Tome’s Machines?

The size of machine tools varies depending on the types, the methods of machining, and the size of workpieces. Let’s take a look at how big the Nakamura’s machines are.

-

Six Key Points to Minimize Chatter in Machining!

If you’ve been involved in machining, you’ve probably experienced “chatter” on the machined surface at least once. Chatter tends to occur more easily, especially in I.D (internal diameter) turning, where tools are extended longer. This time, we will introduce six points to review when chatter occurs during machining.

Latest Articles