Recently updated on July 17th, 2024 at

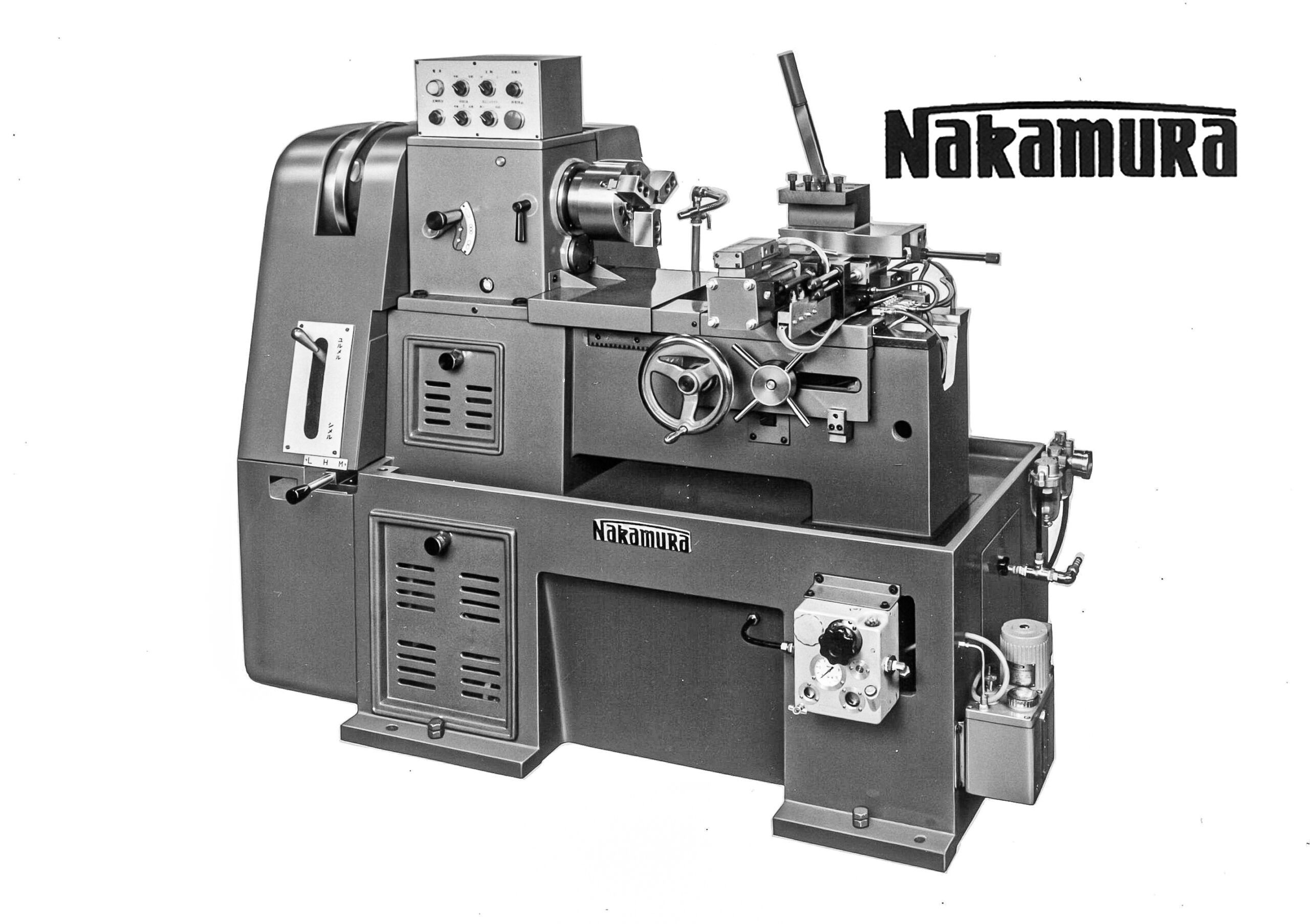

Do you know a machine called a “lathe”? Although rarely seen in our daily lives, it plays an important role in creating all the products around us. In this article, we will explain the processing target of the lathe and the machine configuration.

1. What is a lathe?

A lathe is a machine tool that processes metal by rotating the material to be processed and applying a blade to cut it into a cylindrical shape. For a simple example, imagine peeling an apple. It is like peeling an apple thinly with a knife while slowly rotating the apple. The apple is the material, the rotating device is the spindle, and the knife is the cutting tool. So Lathe is a machine that presses the cutting tool against the rotating material while moving it parallel to the main axis cutting it to form a cylindrical shape.

2. What does it process?

A lathe is a machine tool that specializes in processing cylindrical shapes. It is mainly used to process cylinders and cones. In addition, it can also perform drilling and screw machining. To give you an idea of what kind of parts lathes are used to process, most of the products we are familiar with use parts processed by lathes.

Automotive parts, aircraft parts, construction machinery parts, medical parts, energy-related parts, home appliance parts, semiconductor manufacturing equipment parts, etc. are mostly assembled products using parts processed using lathes. We can process all kinds of materials, including iron, aluminum, stainless steel, brass, castings, and resin.

3. What kind of processing can be done?

A lathe spins a material and presses a tool (insert) against it to process it. It can be used for various types of machining depending on the type of cutting tool used and how it is moved. In general, it is possible to perform outer diameter machining, inner diameter machining, end face machining, thread machining, groove machining, hole machining (drilling), taper machining with an angle such as conical shape, and circular arc machining. A combination of these various machining methods is used to complete a single part.

The process design is to define what kind of cutting tools is used, the processing method and the processing order. The machining is done by changing the tool and moving it in accordance with the process order. Although it requires the skills of a craftsman to operate the machine, it is useful for quick delivery of a single product or for detailed modification of a processed product.

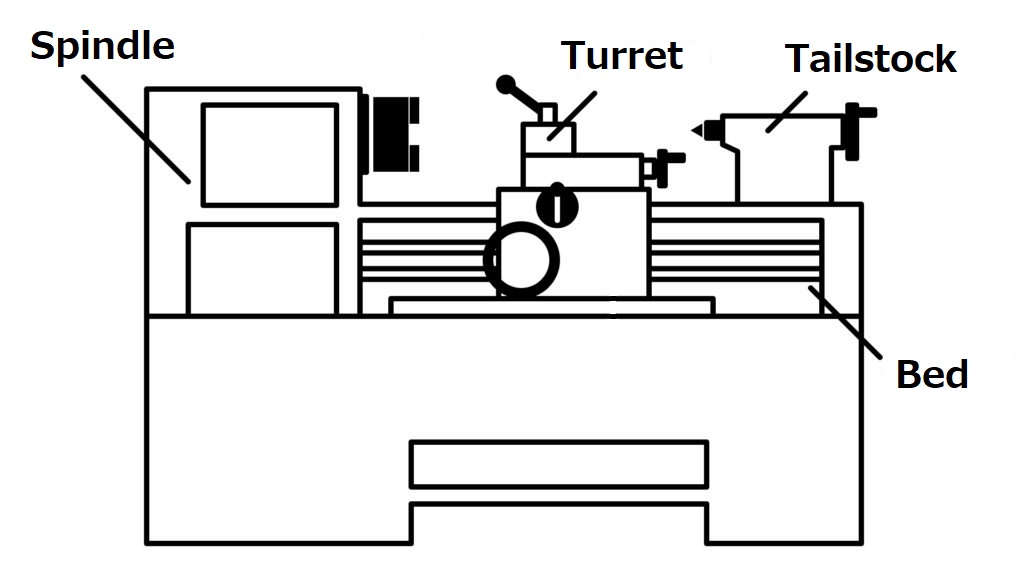

4. Machine configuration

A lathe consists of four main parts: the bed, spindle, turret, and tailstock. Briefly, the main spindle holds the material and rotates it. The turret, where the tool is attached, moves to shape the part to be machined. The tailstock supports the long workpiece. Finally, the bed is the base on which the three platforms are mounted.

In the case of NC lathes, the basic configuration is the same, and the NC device and operation screen are also included.

4-1. Bed

The bed is the foundation of the machine that supports the spindle, turret, and tailstock. If the bed is weak, the spindle and turret mounted on it will be deformed during the movement, making it impossible to perform accurate machining.

Therefore, the design is made with the latest technological capabilities such as material selection and structure design.

4-2. Headstock (Spindle)

Along with the bed, the bearing configuration and balance of the spindle, as well as the rigidity of the headstock, are also important factors in machining accuracy.

4-3. Carriage

The Carriage is the table on which the tool post is mounted and can move in the longitudinal direction on the bed. It consists of a cross slide, a compound rest, a feed table, and a tool post.

4-4. Tail Stock

The tailstock is a platform mounted on the bed opposite the headstock and has a structure that can be moved in the longitudinal direction. It is used to support the workpiece, and by changing the tip, it can also be used for drilling.

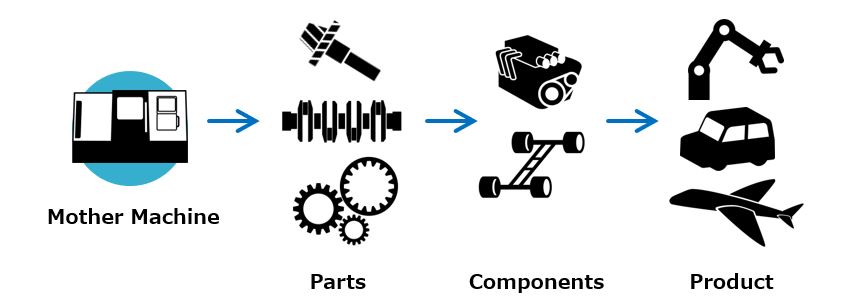

5. Summary

Machine tools are called “mother machines” and are said to be machines that make machines. Among them, lathe is the most used machine tool in the machining process. Although lathes themselves are rarely seen in our daily lives, many of the products we use in our daily lives use parts produced by machine tools. If you see a cylindrical part in your daily life, it may have been produced by a lathe.