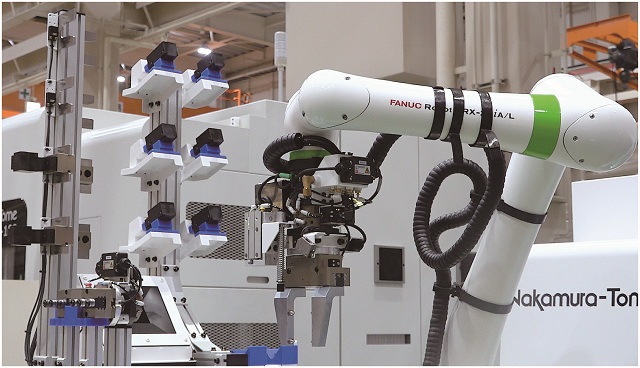

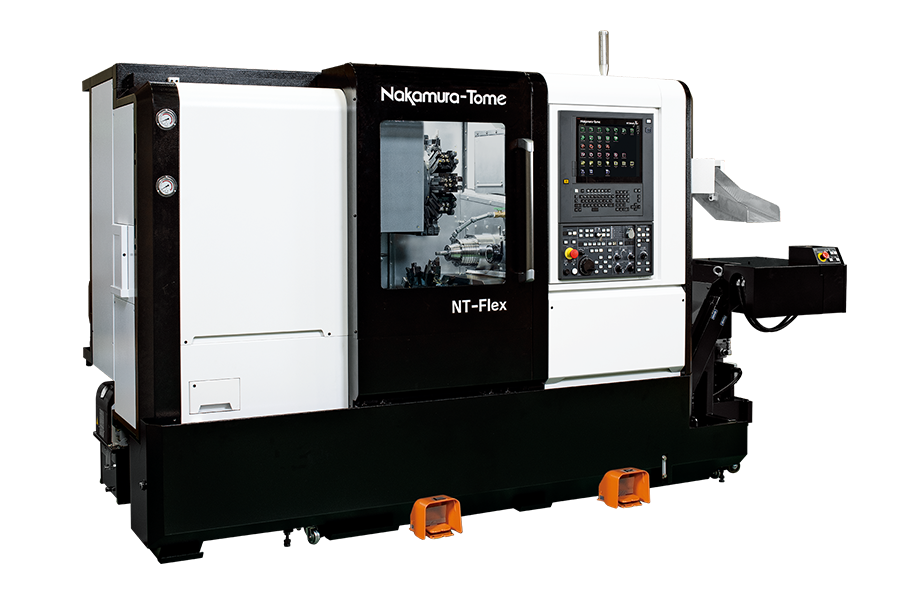

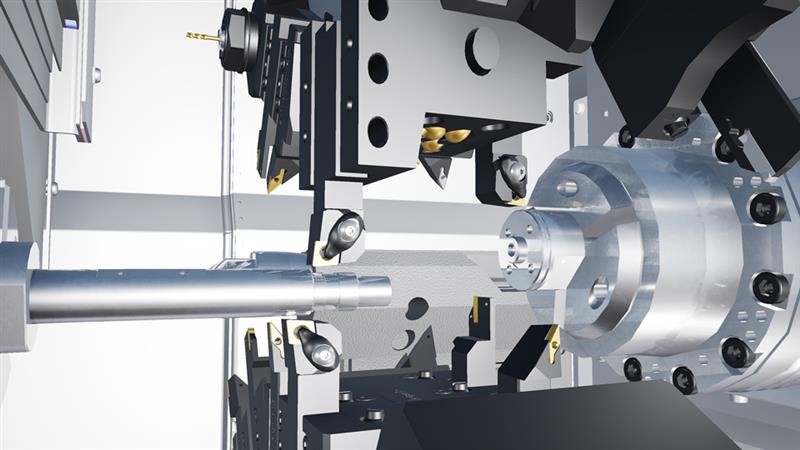

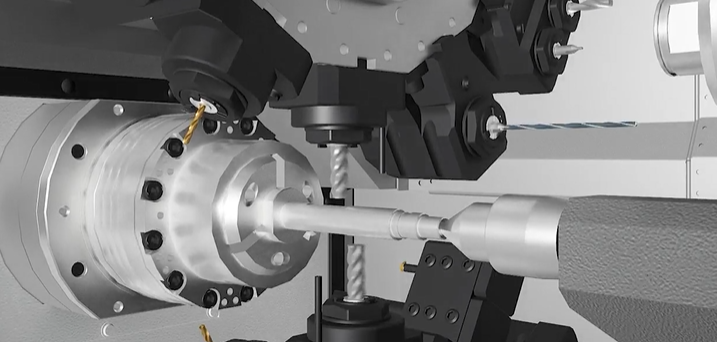

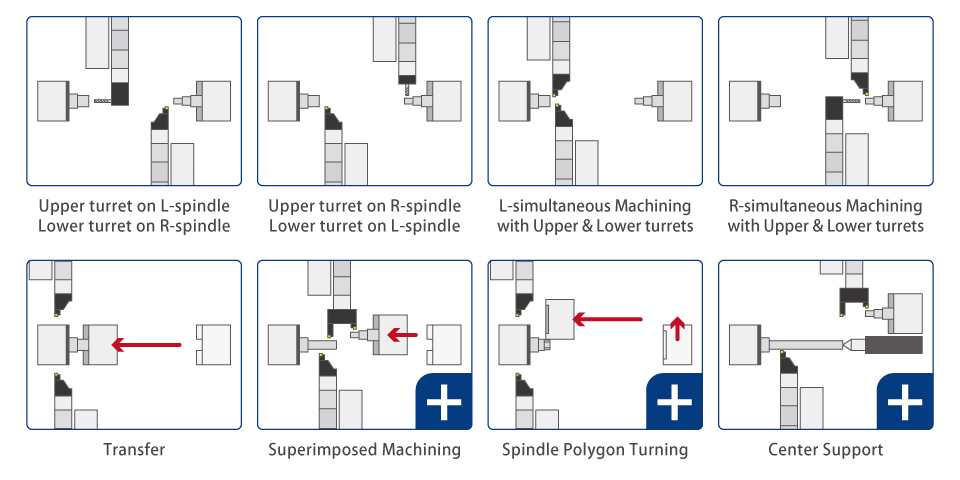

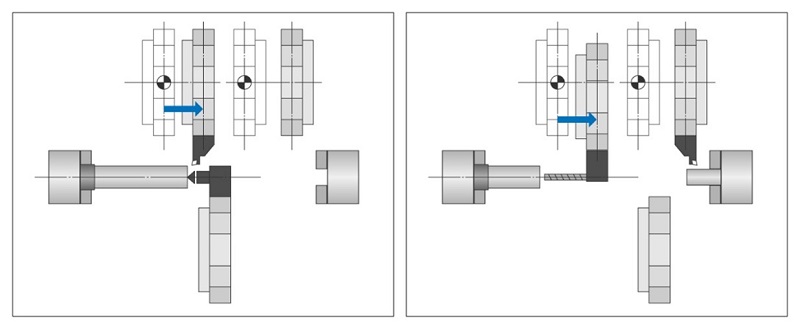

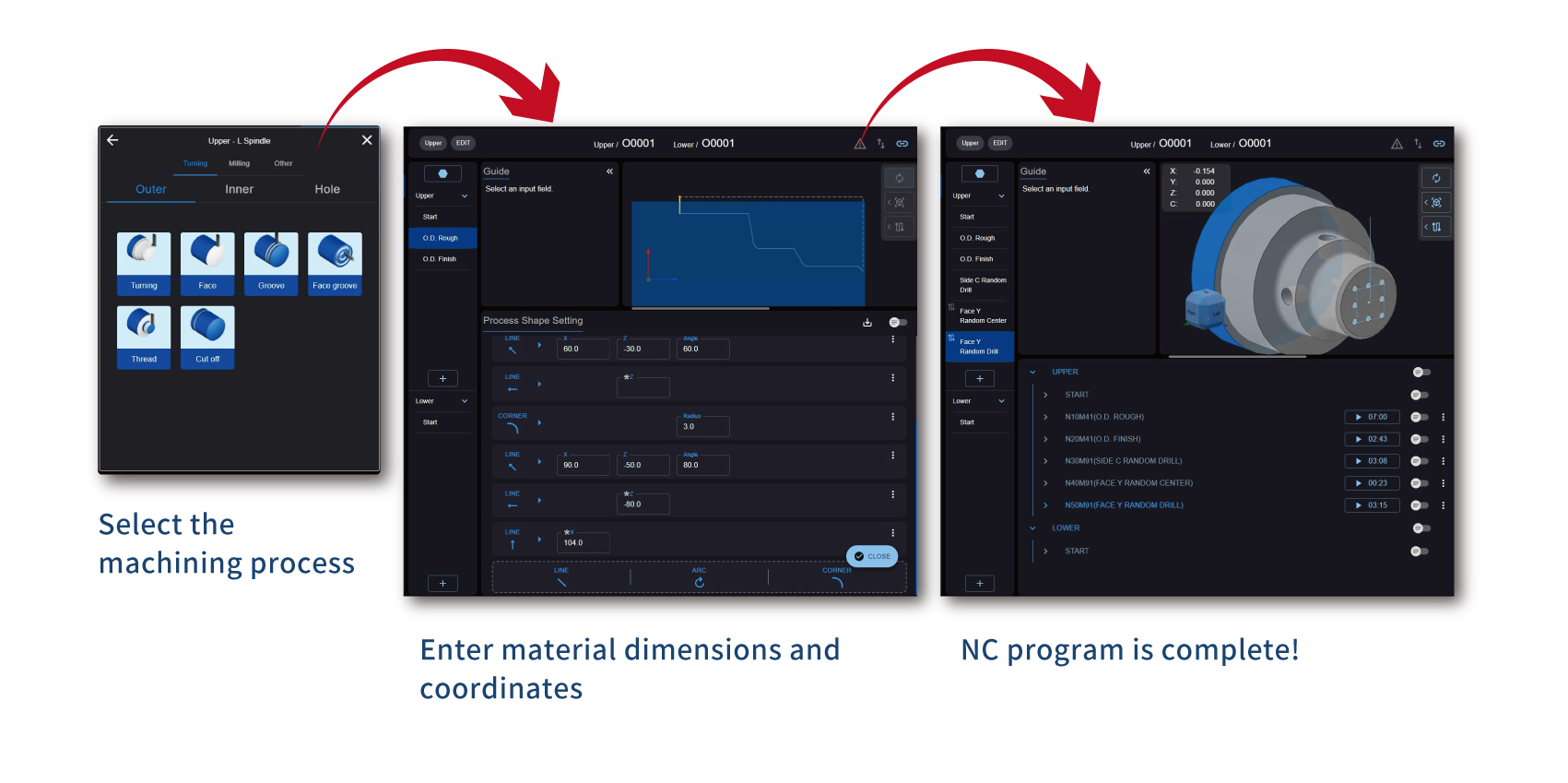

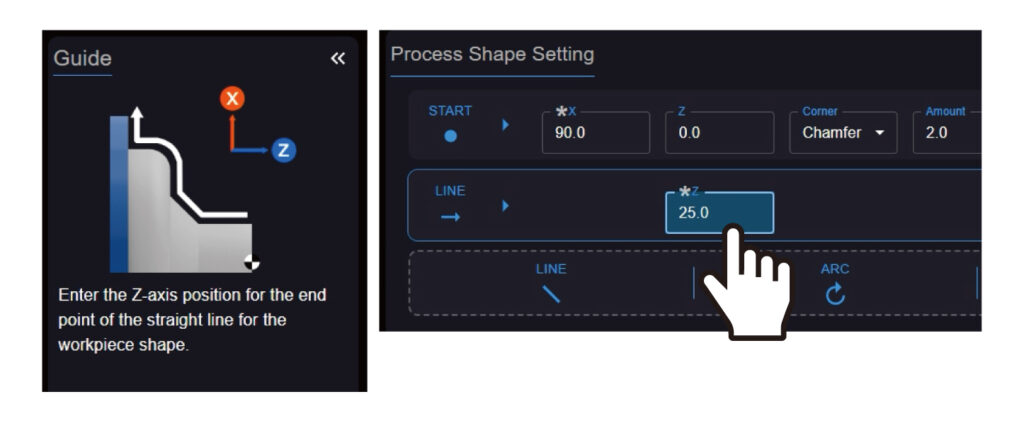

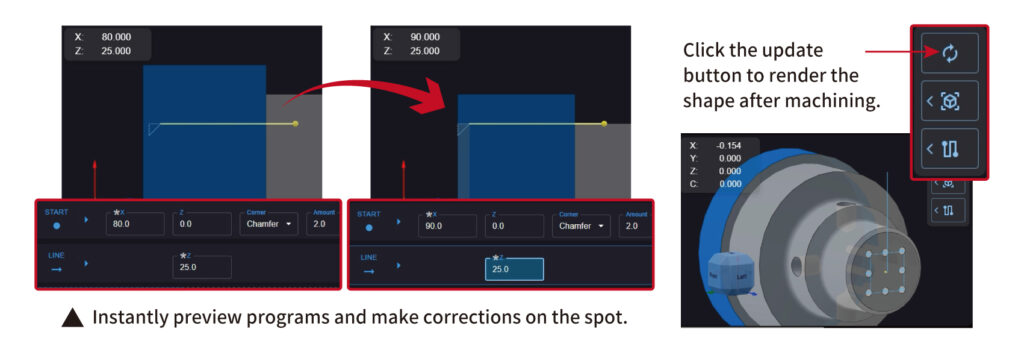

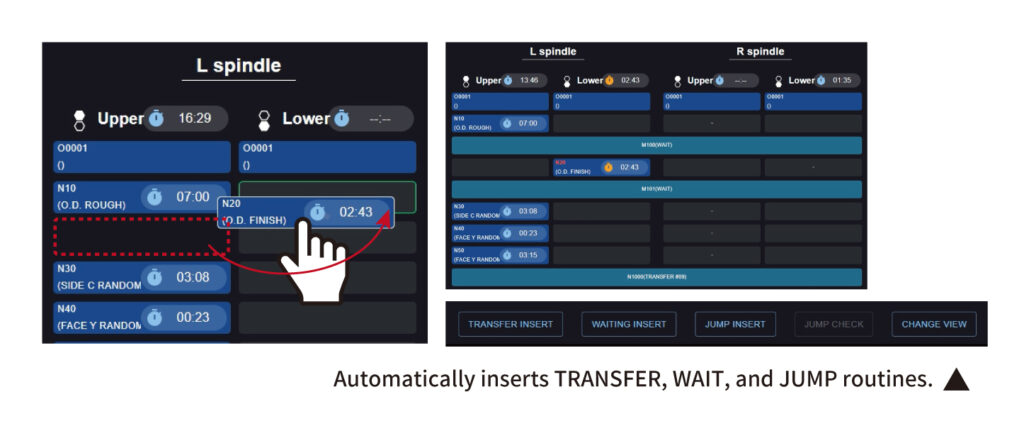

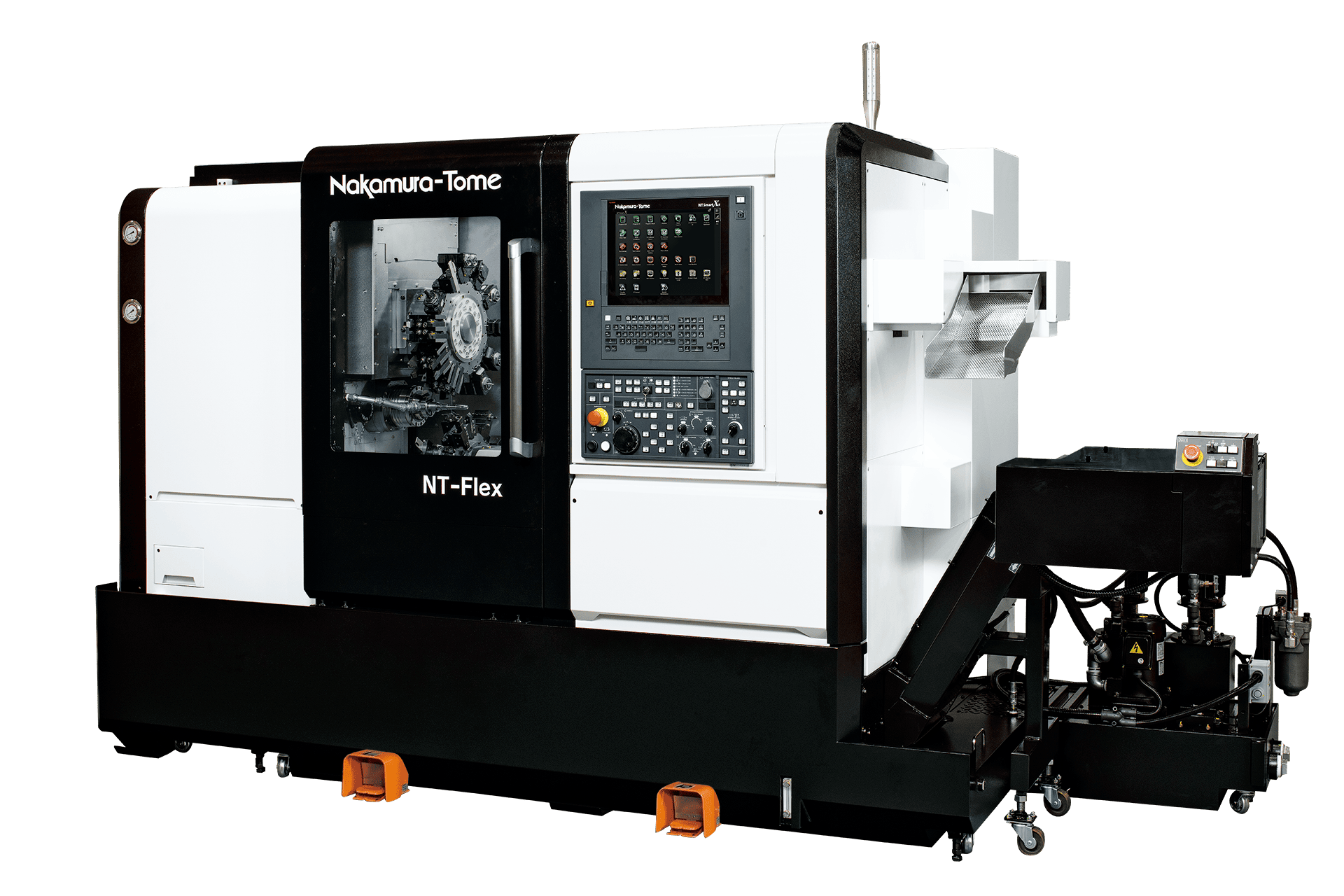

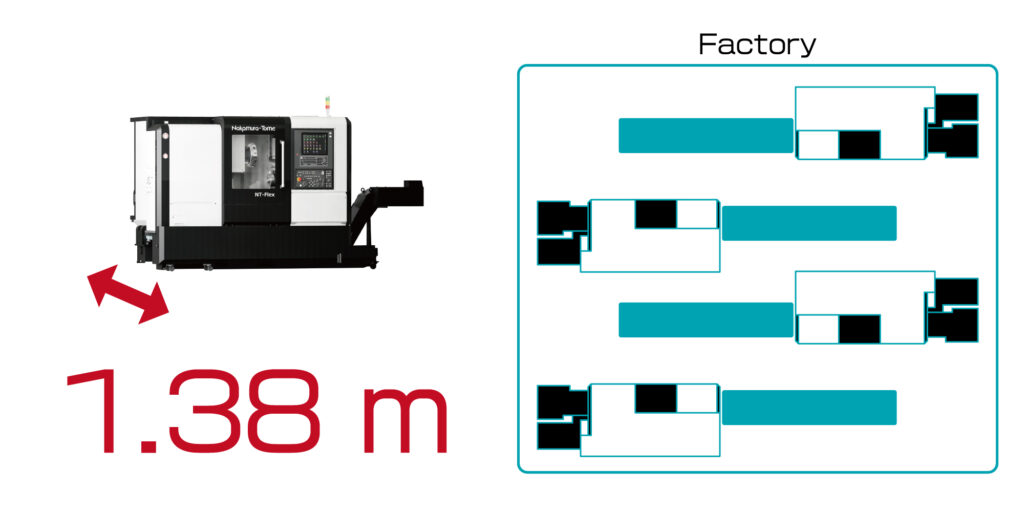

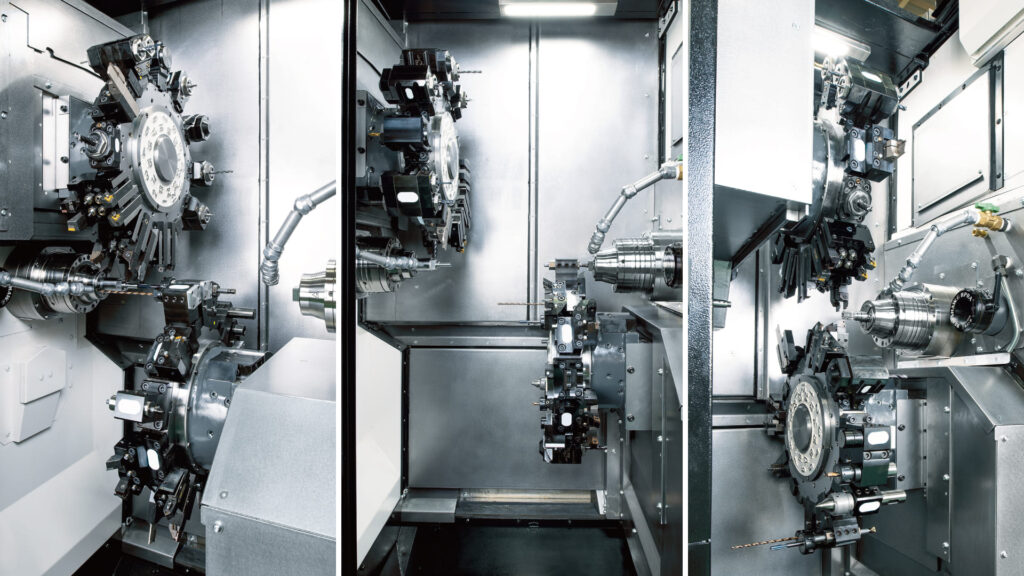

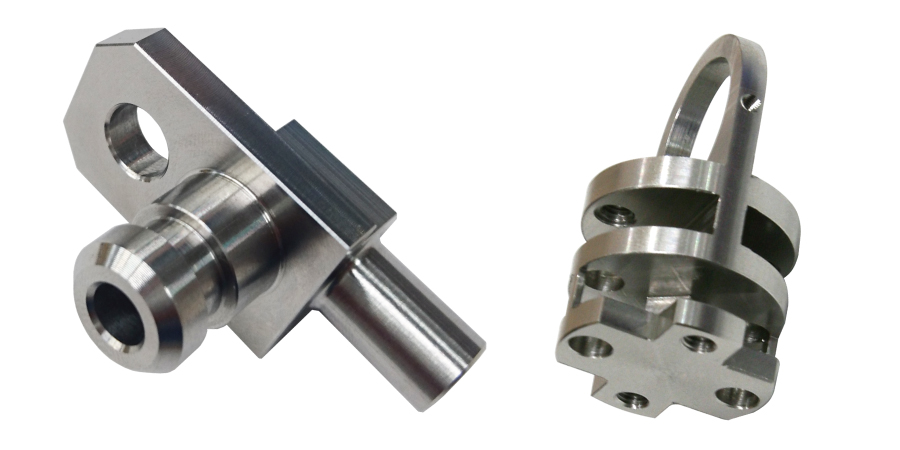

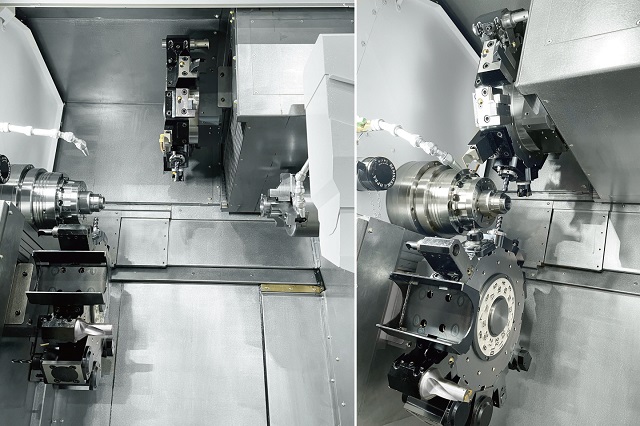

Happy New Year! We would like to express our heartfelt gratitude to our customers, dealers, suppliers, and many other partners whose support enabled us to cut the burden of manufacturing on the shop floors around the world last year. During that time, we all created new value and delivered it to our customers: the compact two-turret multitasking lathe NT-Flex+, the new Conversational NC programming software Protona, the flexible and compact automation system RoboSync-TypeD, and the new specifications for the LC-50 in our optical semiconductor business.

In delivering these new values, we received valuable feedback from many customers. Listening to each customer’s voice made this a truly educational year for us. Moments when customers say, “This is exactly the machine we wanted,” or “Only Nakamura-Tome could do this job,” are priceless. I’ll never forget the sight of the responsible engineer beside me, smiling happily as he heard those words. Furthermore, when customers shared with us, “Actually, we are also struggling with this,” we all discussed how we could further cut the burden on the production floor and are now working towards the next proposal.

Nakamura-Tome began 76 years ago as Nakamura Iron Works, starting with machining parts for textile machinery. As a machining factory, we continued to cut parts, but as we felt the heavy burden on the production floor, we started developing automatic lathes. I believe this background gives us a relatively close viewpoint and sense of closeness with our customers, and I make it a point to share with everyone our commitment to maintaining this approach.

We would be delighted if you could feel free to share any challenges or issues you are facing. Let’s share these challenges together and cut the burden of manufacturing on the shop floor.

We sincerely look forward to moving forward together with you all this year. We have many new announcements planned for the future, so please stay tuned. We look forward to your continued support!

Nakamura-Tome Precision Industry Co., Ltd.

President and CEO

Shogo Nakamura

Protona introduction video

URL:https://www.youtube.com/watch?v=EOICl4sx-NU

NT-Flex+ introduction video